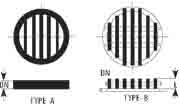

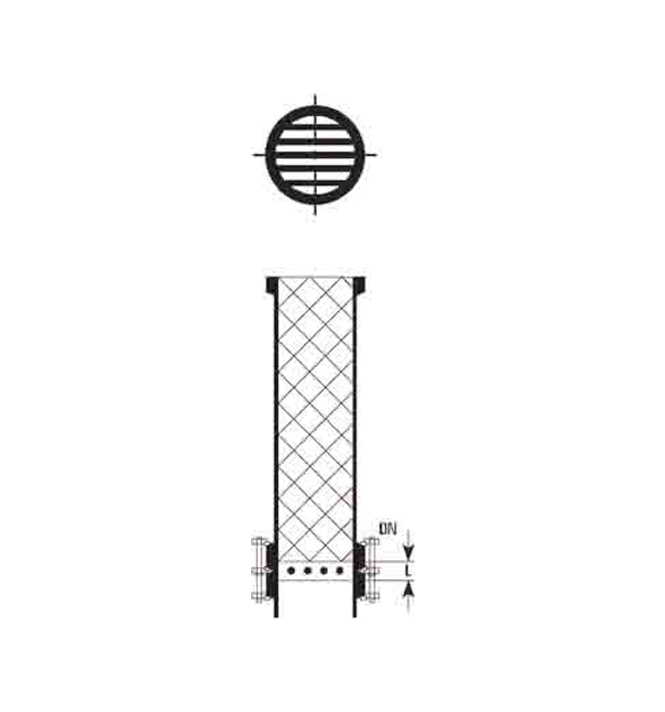

Packing supports Type A are made of fused glass rods. Packing supports Type B (heavy duty) are made of glass plates vertically arranged and tied with PTFE tie rods

|

Cat. Ref. |

DN |

L |

Cross Section Area |

Max. Load Kgs. |

Minimum Packing Size |

Type |

|

CP3* |

80 |

10 |

45% |

10 |

12 |

A |

|

CP4* |

100 |

12 |

50% |

15 |

15 |

A |

| CP6* | 150 | 55% | 30 | 25 | A | |

|

CP9* |

225 |

19 |

60% |

50 |

25 |

A |

|

CP12* |

300 |

19 |

65% |

75 |

25 |

A |

|

HD16 |

400 |

70 |

70% |

150 |

25 |

B |

|

HD18 |

450 |

70 |

70% |

200 |

25 |

B |

|

HD24 |

600 |

95 |

70% |

300 |

40 |

B |

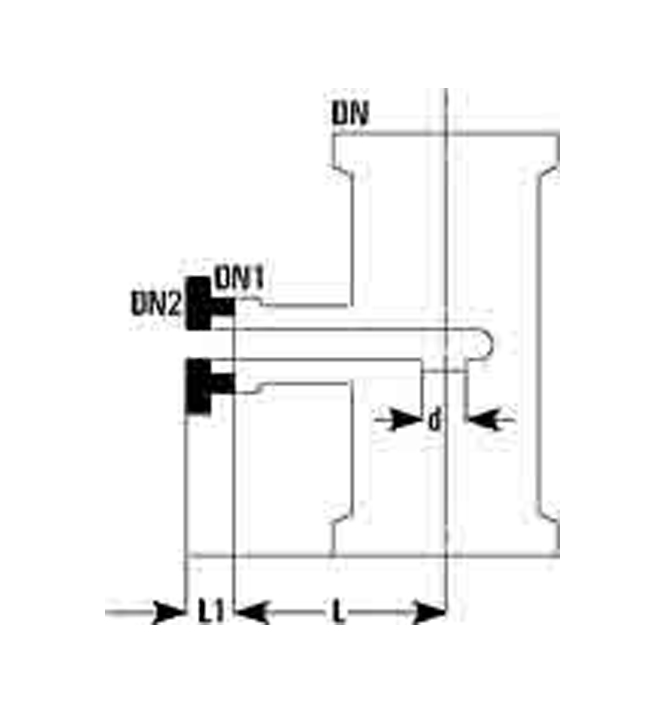

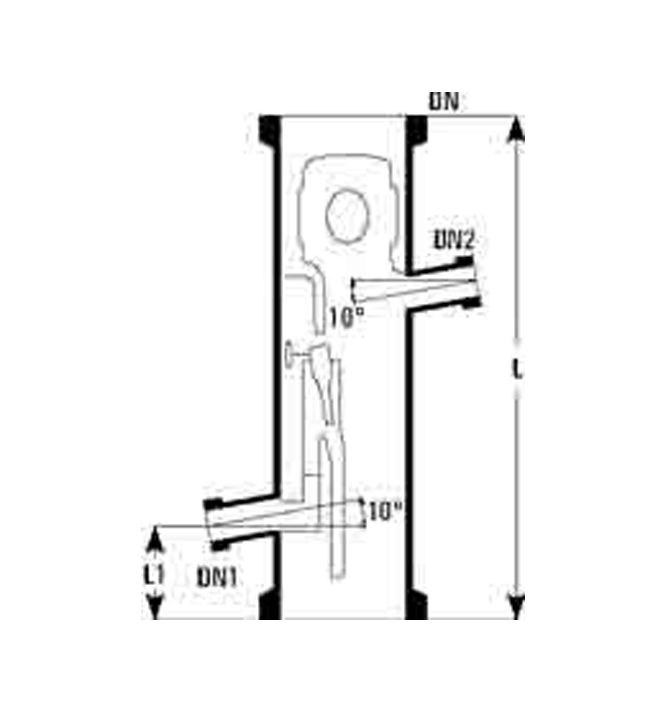

Column adaptors with DN2 of different size (maximum equalant to DN1) can be manufactured with the same dimensions.

PTFE PERFORATED PLATES

These are used as packing retainers to prevent the packing from lifting due to vapour velocity. These can be clamped between two components without using any gasket.

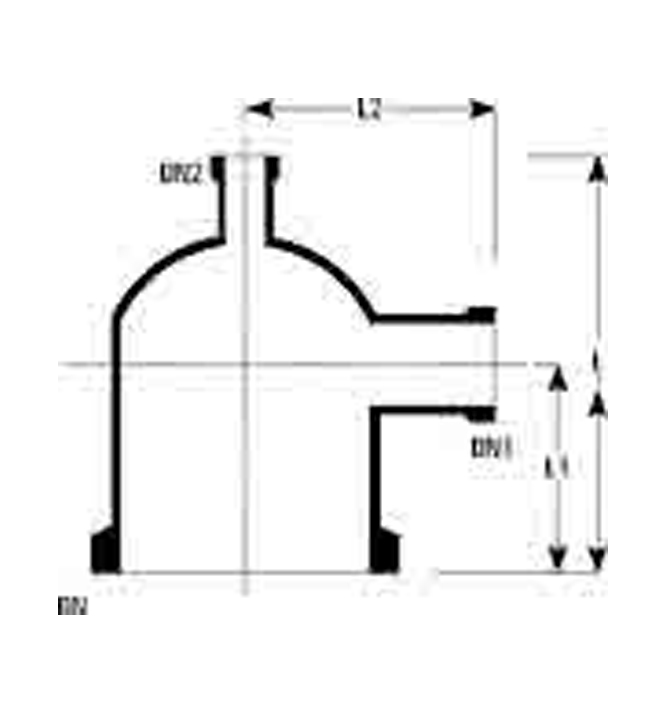

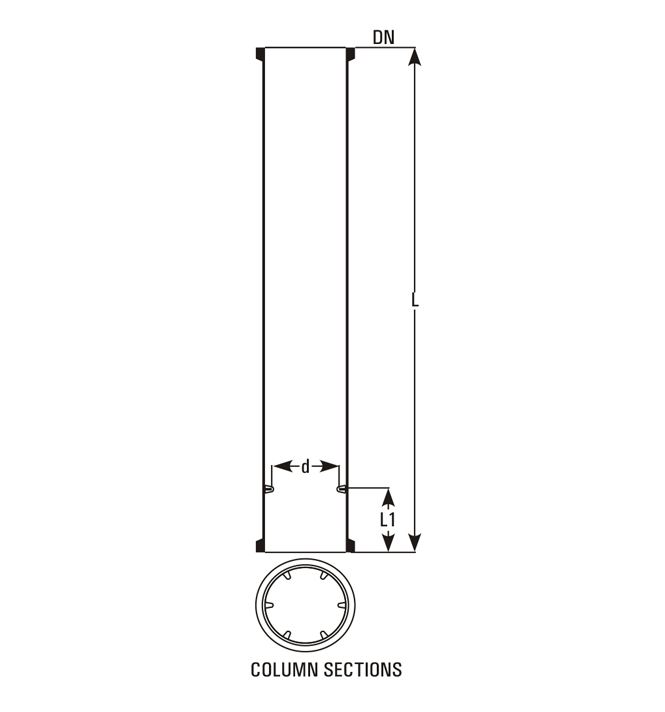

SUPPORT PLATE ASSEMBLY

Support plate assembly can be coupled with a pipe section (PS) , so as to use the pipe section as a column section and to fill packings into it. This system provides following advantages over the conventional system of using column section with a packing support.

- Higher cross section area.

- More packing height.

- No separate inventory of column sections.

- SDelivery period of pipe section are shorter.

This assembly consist of a glass support plate, a metal flange, a PTFE ‘O’ ring and nut-bolts.

|

Cat. Ref. |

DN |

L |

CrossSection Area |

Max. Load Kgs. |

Suitable Packing Size |

|

LBE3* |

80 |

25 |

70% |

20 |

12 |

|

LBE4* |

100 |

25 |

70% |

30 |

15 |

|

LBE6* |

150 |

50 |

70% |

60 |

25 |

|

LBE9* |

225 |

50 |

80% |

90 |

25 |

|

LBE12* |

300 |

50 |

80% |

150 |

25 |

* marked items are available fast.