Borosilicate Glass

Borosilicate Glass 3.3

Superior borosilicate glass components are acquired from leading manufacturers using the best raw materials.

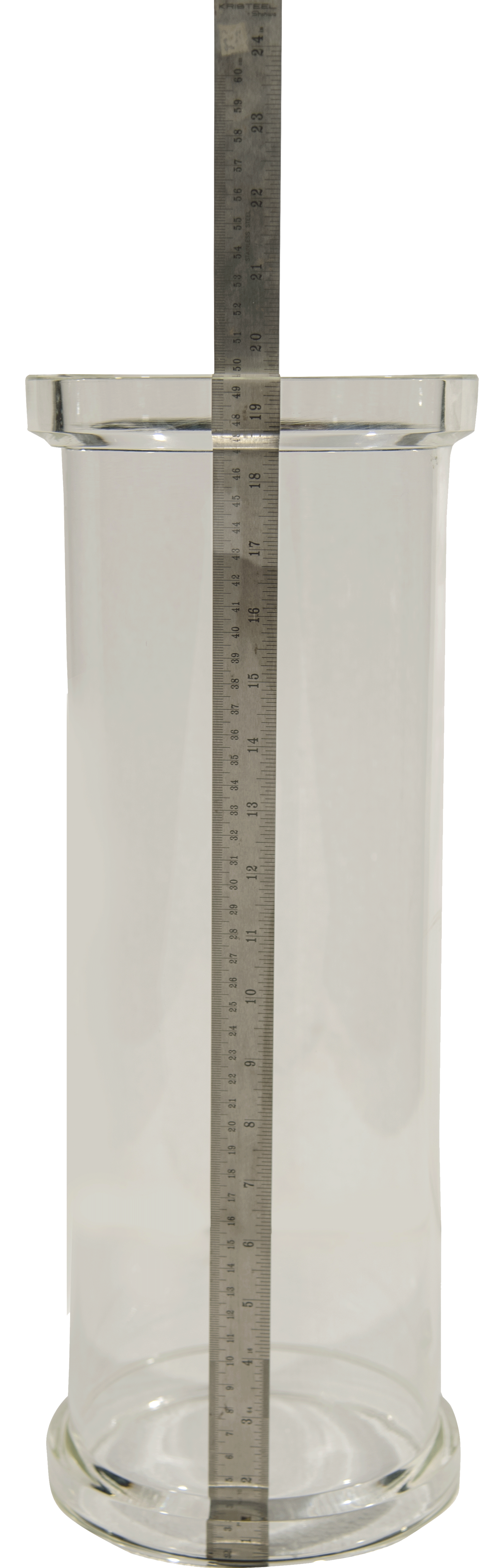

We specialize in providing glass components manufactured by the best European Borosilicate Glass 3.3 tubing supplier. Our products meet all important standards, including DIN ISO 3585 and ASTM E438 Type I, Class A, ensuring high precision and optical qualities. As a dedicated supplier, we take pride in providing quality on par with leading manufacturers worldwide.

Borosilicate glass is an exceptional standardized glass for the construction of plants and infrastructure in the chemical, dyestuff, culinary, pharmaceutical, and petrochemical sectors.

Its continuously increasing popularity is due to numerous advantages over traditional materials.

- Excellent corrosion resistance

- Smooth, pore-free layer

- Transparency

- Chemical inaction

- No influence on taste or odor

- Physiological inflexibility

Borosilicate glass 3.3 is chosen for its distinct chemical and physical features. Borosilicate glass is made up of oxides. The main modifiers/fluxes are silica (SiO2), magnesium (MgO), and lead oxide.

The chemical and physical qualities of any glass are determined to variable degrees by its chemical composition.

Chemical Composition

The composition of borosilicate glass used for chemical plants has following approximate composion.

| SiO2 – 80.6% | B2 O2 – 12.5% |

| Na2O – 4.2% | Al2O3 – 2.2% |

Resistance to Chemical

Except for hydrofluoric acid (HF), phosphoric acid (H3Po4), and hot, strong caustic solutions, borosilicate glass 3.3 is inert to practically all compounds. Hydrofluoric acid has the most serious effect, even when present in solutions in PPM (parts per million).

When cold, phosphoric acid and caustic solutions do not cause any difficulties, but at high temperatures, corrosion occurs. Caustic solutions with concentrations of up to 30% can be handled safely at ambient temperature.

Under actual operating conditions, turbulence and trace amounts of other compounds in the solution may raise or decrease the rate of attack. As a result, specific data for corrosion caused by caustic solutions cannot be provided.

Thermal Properties

- Linear Coefficient of Thermal Expansion

The coefficient of thermal expansion of borosilicate glass 3.3 across the temperature range of 0 to 300°C is 3.3 x 10-6/°C. This is extremely low when compared to other glasses and metals. This is why borosilicate glass is commonly referred to as low expansion borosilicate glass.

- Specific Heat

The average specific heat between 25°C and 300°C is 0.233 kcal/kg, °C.

- Thermal Conductivity

The conductivity of heat is 1.0 kcal/hr/m°C. Above the allowable operating temperature range.

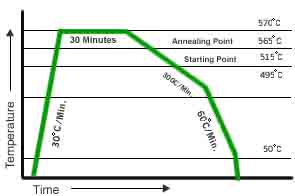

Annealing

Annealing is the technique of heating and holding glass for a set period of time to relieve internal stresses. Cooling under regulated circumstances is critical to ensuring that no stresses are reintroduced during chilling/cooling.

Reshapeing

The following graph depicts the typical temperature at a certain viscosity, which is required for glass reshaping.

| Lower cooling temperature | 1024 poise | 515°C |

| Upper cooling temperature | 1013 poise | 565°C |

| Softening point | 107 poise | 795°C |

| Reshapeing point | 104 poise | 120° C |

Mechanical Properties of Borosilicate Glass

The lack of of ductility in glass reduces stress equalization at local abnormalities or faults, therefore the breakage strength varies significantly around a mean value. This latter occurs with a tensile strength of about 700 kg/cm2.

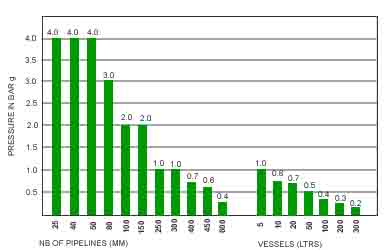

To account for the dispersion of breaking stress, a significant safety factor is utilized when estimating the wall thickness required to allow operation up to the working pressure values listed in the table.

Optical Properties of Borosilicate Glass

Borosilicate glass has no apparent resistance in the visible portion of the spectrum, therefore it appears clean and colorless. In photochemical processes, ultraviolet transparency is particularly important.

According to the transmittance of material in the ultraviolet area, photochemical reactions such as chlorination and sulpho chlorination can take place there.

Permissible Operating Conditions For Borosilicate Glass

The permitted internal operating pressure is determined by the nominal diameter of the glass components and the working temperature.

In the case of a unit having many combinations, such as vessels, filters, or heat exchangers, the overall permitted internal gauge pressure is always determined by the components with the lowest permissible operating gauge pressure. All components are acceptable for use in complete vacuum.

Bar is a unit of absolute pressure. The value for maximum recommended working pressure represents pressure above atmospheric.

Working Temperature

Borosilicate glass preserves its mechanical strength and will only deform when temperatures approach its strain point.

The practical upper limit for operating temperature is much lower, and it is controlled by temperature differentials in the glass, which are dependent on the relative temperature differentials in the glass, which are dependent on the relative temperature of the equipment's contents and the external surroundings.

Borosilicate glass can be safely used at temperatures up to 250 °C as long as it is not subjected to abrupt temperature changes that cause thermal shock.

It should be noted that in entire plants made not only of borosilicate glass, but also of other materials such as PTFE, the recommended max.

The operating temperature is 200°C. Operating temperatures may need to be adjusted to account for the impacts of other parameters such as pressure, thermal cycling, rapid heating and cooling, etc.

The degree of thermal shock (typically described as abrupt freezing or heating) that it can withstand is determined by a variety of parameters, including operating circumstances, forces imposed while supporting the equipment, and glass wall thickness.

It is therefore undesirable to introduce abrupt temperature fluctuations. However, temperatures up to 120 °C can be accommodated.

The tensile strength of borosilicate glass increases at sub-zero temperatures, allowing equipment to be utilized safely at temperatures as low as -50 °C for XTRONG and components.

Composite Material

Over the previous two decades, new or improved corrosion-resistant plant construction materials have been developed. PTFE, tantalum, titanium, graphite, and, of course, Borosilicate 3.3 glass are all common examples.

The use of various corrosion-resistant materials, as well as the individual benefits of each, allows for both safe and cost-effective construction.

Borosilicate Glass/PTFE

Borosilicate glass with PTFE is very important for the building of glass installations, for example. In seals, bellows, stirrers, pumps, heat exchangers, column inserts, and so on.

PTFE has been used with glass due to its outstanding mechanical and thermal qualities. They have near-universal fluid compatibility. In comparison to others, the wear life is extremely short. PTFE, in particular, is maintenance-free and has cryogenic stability as well as non-wetting properties.

The service temperature of PTFE is regarded to be -50°C to +200°C

Electrical Characteristics - Borosilicate Glass

Glass is a poor electrical conductor, therefore surface conductivity is negligible and fluctuates with the amount of water absorbed on the glass surface. At 200 degrees Celsius, the specific conductivity is 10 ohm/cm. The dielectric coefficient varies according to the current frequency.

Density Borosilicate Glass

- Density of glass at 20°C(J)=2.23g/cc

- Modulus of elasticity (E)=6.3 KN/mm2

- Poissions ratio=0.2

With X Bonding

Without X Bonding

Extra Protection of Glass Components 'X Bonding'

X BONDING provides extra protection for common glass components. The primary benefit of X Bonding systems is that if the glass is accidentally broken, the bonded wrapping provides additional protection against the risk of injury, the discharge of corrosive fluids, or the loss of valuable products.

X BONDING is a glass bonded fibre coating that provides enhanced protection to glass components. This has a little negative influence on the transparency of the glass, making it translucent rather than transparent.

Permissible Operating Temperature

The maximum allowed operating temperature for X-Bonding is 130' C, unless limited by the component's unique operating temperature.

Permissible Operating Pressure

The permitted operating pressure for X Bonded components is the same as that for conventional glass components.

Thermal Shock

Despite the heating resulting from X Bonding, the thermal shock properties of normal glass components remain unchanged.

Vacancy for Senior Process Design Engineer