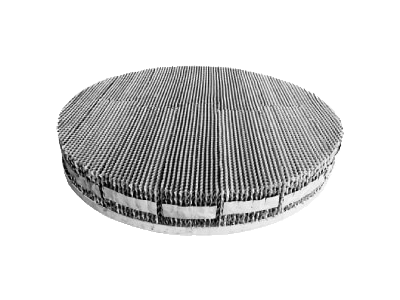

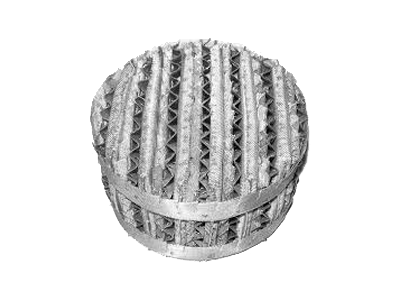

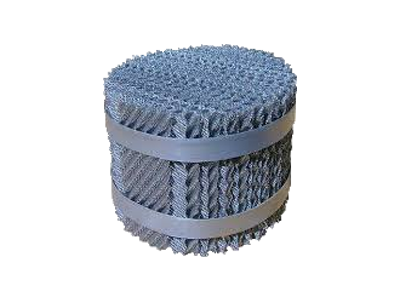

High-Performance Structured Packings for Increased Column Efficiency

At Goel Impex, we offer a superior range of Structured Packings engineered to optimize mass transfer operations in distillation, absorption, and stripping columns. As a trusted Structured Packing Manufacturer and Structured Packing Supplier, we specialize in delivering customized solutions that meet the highest standards of efficiency, durability, and chemical resistance.

What is Structured Packing?

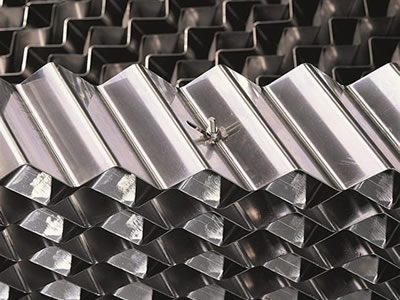

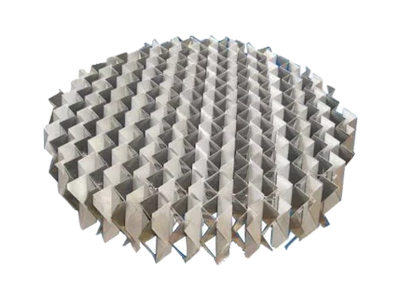

Structured packing is a carefully designed packed structure made from corrugated sheets of metal, plastic, or glass, stacked uniformly to create a regular, geometric pattern inside the column. This design maximizes surface area while minimizing pressure drop, enabling higher separation efficiency and capacity.