A Distillation Column is a key component in the separation processes used in various industries. It is a vital tool for separating components in a mixture based on differences in boiling points. Whether used in petroleum refining, chemical processing, or food industries, distillation columns play a crucial role in producing high-purity liquids.

Goel Impex offers top-quality Distillation Columns designed for efficiency and durability, suitable for both small-scale and industrial applications.

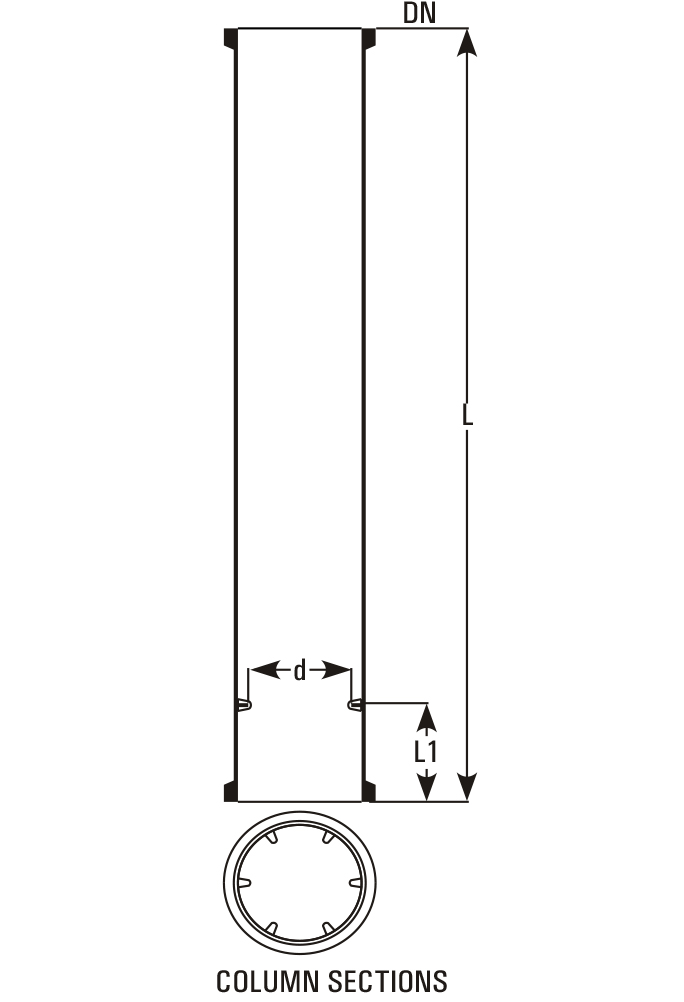

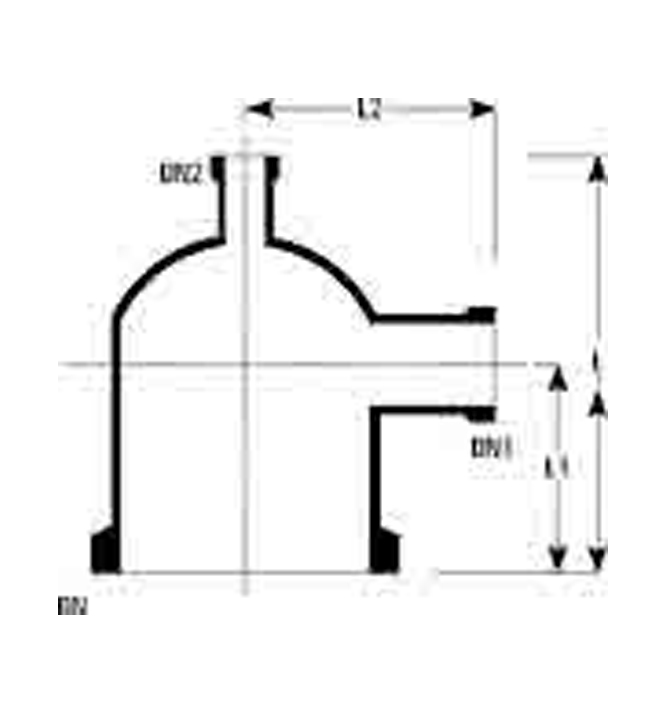

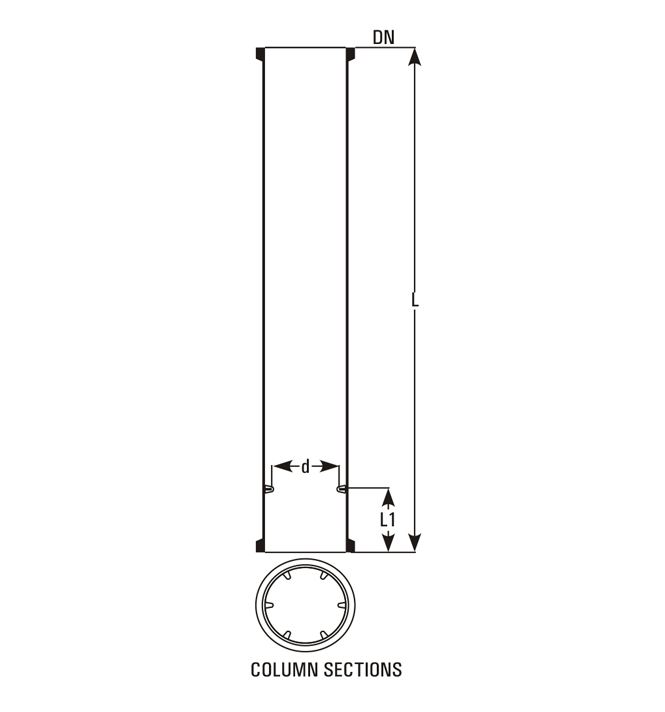

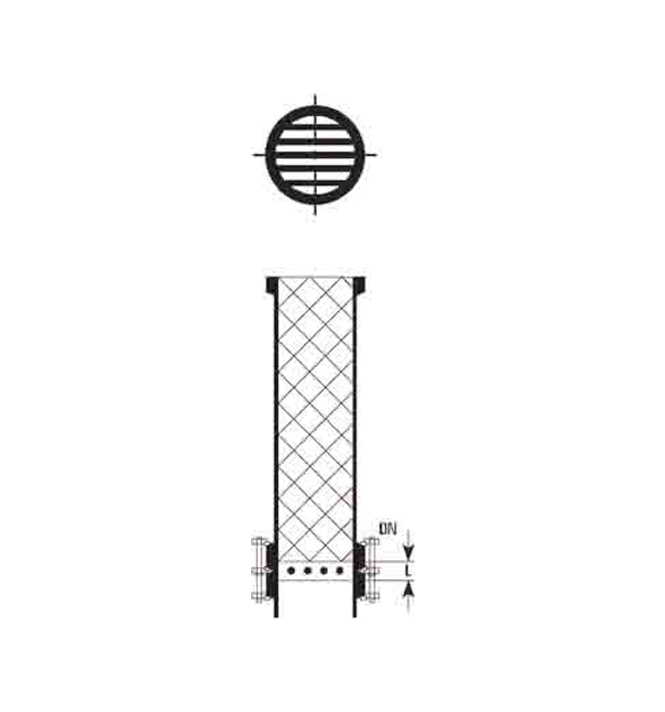

Distillation Columns are designed using either pipe sections with support plates or column sections with packing supports, ensuring efficient separation processes.

Each Distillation Column features a durable fused shelf, providing a stable base for packing support, improving performance and reliability.

A glass distillation column is a vertical cylindrical structure designed for the efficient separation of liquid mixtures through fractional distillation. It features trays or packing materials that enhance vapor-liquid contact, improving separation efficiency and ensuring high-purity output.

In a fractional distillation process, the mixture is heated to vaporize the component with the lowest boiling point. As the vapor ascends through the distillation column, it interacts with liquid on trays or packing materials, achieving equilibrium and enabling precise separation of different components.

The condensed vapors, known as distillate, are collected for further processing, while the remaining liquid, referred to as bottoms, contains higher boiling point components.

A glass distillation column is widely used in industries such as petroleum refining, chemical processing, pharmaceuticals, and beverage production. It plays a critical role in ensuring product purity, consistency, and efficiency in industrial applications.

|

Cat. Ref. |

DN |

L |

L1 |

Minimum packing Size |

Usual packing Size |

|

CS3/1000 |

80 |

1000 |

75 |

9 |

12 |

|

CS4/1000 |

100 |

1000 |

75 |

12 |

15 |

|

CS6/1000 |

150 |

1000 |

75 |

15 |

25 |

|

CS6/1500 |

150 |

1500 |

75 |

15 |

25 |

|

CS9/1000 |

225 |

1000 |

100 |

20 |

25 |

|

CS9/1500 |

225 |

1500 |

100 |

20 |

25 |

|

CS12/1000 |

300 |

1000 |

100 |

25 |

25 |

|

CS12/1500 |

300 |

1500 |

100 |

25 |

25 |

|

CS16/1000 |

400 |

1000 |

150 |

25 |

25 |

|

CS16/1500 |

400 |

1500 |

150 |

25 |

25 |

|

CS18/1000 |

450 |

1000 |

150 |

25 |

25 |

|

CS18/1500 |

450 |

1500 |

150 |

25 |

25 |

|

CS24/1000 |

600 |

1000 |

200 |

40 |

40 |

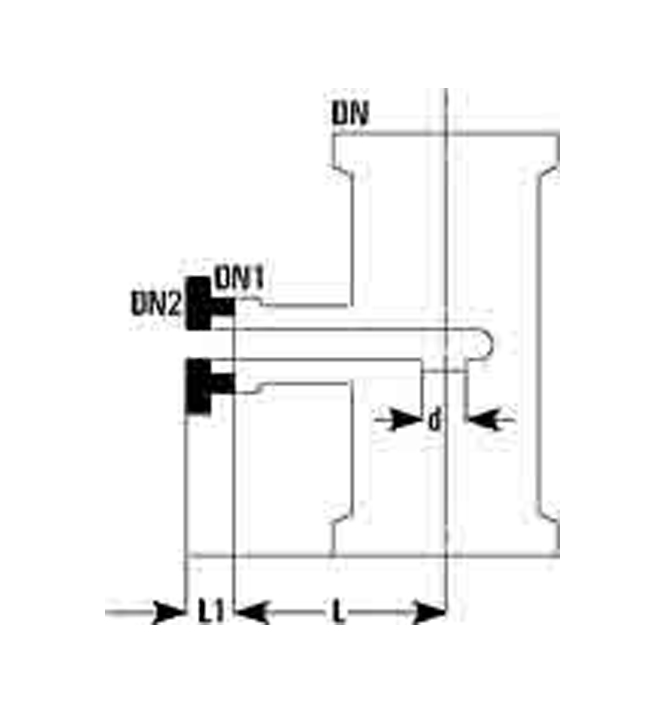

Column adaptors with DN2 of different sizes (maximum equivalent to DN1) can be manufactured with the exact dimensions.

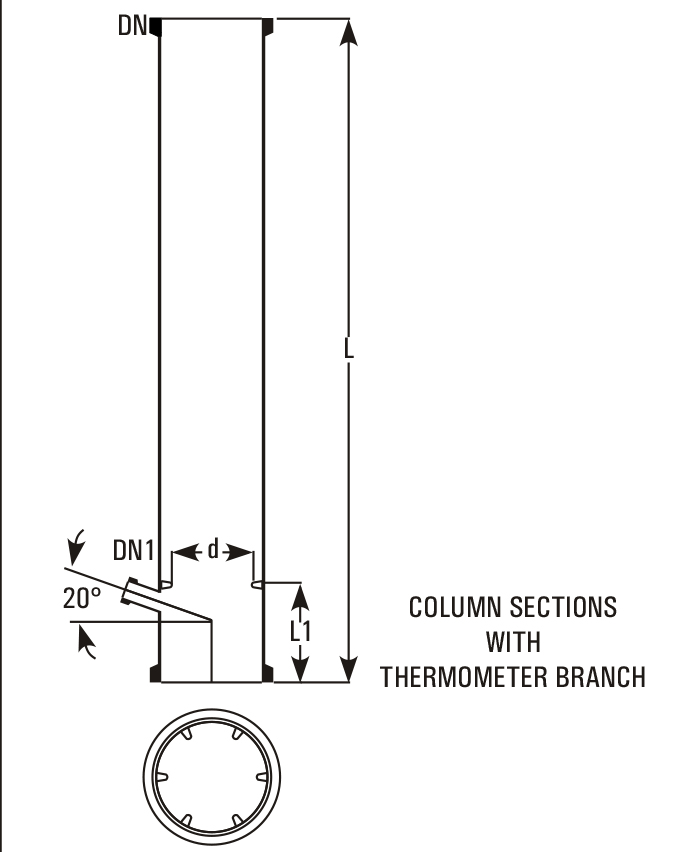

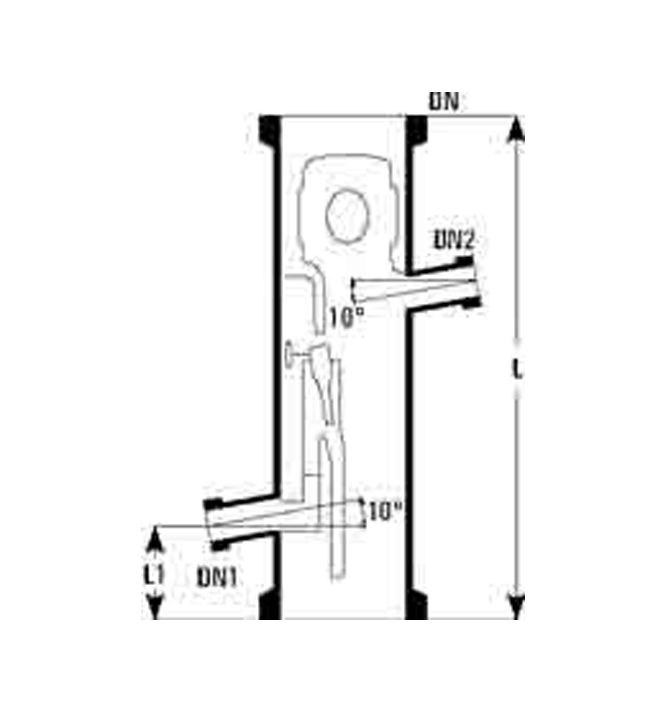

Column Sections with Thermometer Branch

The above distillation column can be provided with a thermometer branch below the packing shelf at a 20° slope.

|

Cat. Ref. |

DN |

DN1 |

L |

L1 |

d |

|

CST3/1000 |

80 |

25 |

1000 |

125 |

50 |

|

CST4/1000 |

100 |

25 |

1000 |

125 |

75 |

|

CST6/1000 |

150 |

25 |

1000 |

125 |

125 |

|

CST6/1500 |

150 |

25 |

1500 |

125 |

125 |

|

CST9/1000 |

225 |

25 |

1000 |

150 |

175 |

|

CST9/1500 |

225 |

25 |

1500 |

150 |

175 |

|

CST12/1000 |

300 |

25 |

1000 |

150 |

250 |

|

CST12/1500 |

300 |

25 |

1500 |

150 |

250 |

|

CST16/1000 |

400 |

25 |

1000 |

200 |

250 |

|

CST16/1500 |

400 |

25 |

1500 |

200 |

350 |

|

CST18/1000 |

450 |

25 |

1000 |

200 |

400 |

|

CST18/1500 |

450 |

25 |

1500 |

200 |

400 |

|

CST24/1000 |

600 |

25 |

1000 |

250 |

540 |

What is a Distillation Column?

A Distillation Column is a vertical cylindrical tower used in the process of distillation to separate liquid mixtures. It operates on the principle of heating the mixture to separate components with different boiling points, and it is widely used in the production of chemicals, pharmaceuticals, and petroleum. The column facilitates the separation by providing an environment for vaporization and condensation within the column.

Types of Distillation Columns

At Goel Impex, we provide a range of distillation columns to suit different applications:

Continuous Distillation Column: Continuous distillation columns operate without interruption, making them ideal for large-scale industrial processes. These columns handle a constant feed of the mixture, producing a steady output of separated components.

Tray Distillation Column: This type features a series of horizontal trays or plates to separate components as the liquid ascends through the column. It is ideal for handling large volumes of liquid mixtures.

Packed Distillation Column: In this design, the column is filled with packing materials, typically in the form of rings or saddles. These improve contact between vapor and liquid phases and are used in situations requiring efficient mass transfer.

Fractional Distillation Column: This is used for fractional distillation, where different components of a mixture are separated based on their boiling points. It is commonly used in petroleum refineries and chemical industries.

Industrial Distillation Column: These are built for large-scale industrial use and designed to handle substantial volumes of liquid for continuous distillation processes.

Multi-Column Distillation Column / Plant: This system involves multiple distillation columns arranged in a sequence, often used for the separation of highly complex mixtures.

Distillation Column Design and Diagram

The Distillation Column Design includes the careful selection of materials, shapes, sizes, and internal components to optimize the separation process. A Distillation Column Diagram typically shows the key components, such as the feed inlet, distillation trays or packing, condenser, and reboiler.

Key Components in the Distillation Column:

Column diameter: The diameter of the column is determined based on the flow rate of the mixture and the desired separation efficiency.

Height: The height of the column is important for providing adequate contact time between the vapor and liquid phases.

Tray or packing type: Depending on the application, you can choose between tray or packed columns to optimize performance.

Reboilers and Condensers: These heat exchangers are essential for providing the necessary heat to the column and condensing the vapor at the top.

Overhead and Bottom Products: The purified components that are collected at the top and bottom of the column, respectively.

Distillation Column Parts

A typical Distillation Column consists of several important components:

Column Shell: The outer structure that houses the entire system.

Trays/Packings: Internal components that help in separating the vapor and liquid phases.

Reboiler: A heat exchanger that supplies the heat required for distillation.

Condenser: The component that cools the vapor to form a liquid.

Vapor-liquid Interface: This is the surface where the separation takes place.

Feed Inlet: Point where the mixture is introduced into the column.

Distillate Outlet: Outlet for the purified product.

Residue Outlet: Outlet for the remaining mixture after separation.

Reflux Drum: Collects condensed vapors and returns a portion to the column for improved separation.

Distillation Column Working Principle

The Distillation Column Working Principle is based on the process of vaporization and condensation. As the liquid mixture is heated in the reboiler, the more volatile components vaporize and rise through the column. These vapors come into contact with the trays or packing material, where they condense and re-evaporate, achieving separation. The components with higher boiling points condense at lower levels, while those with lower boiling points rise higher in the column.

Common Issues in Distillation Columns

Some common operational issues in Distillation Columns include:

Flooding in Distillation Column: This occurs when the liquid flow rate is too high, leading to a buildup of liquid in the column, which can hinder efficient separation.

Weeping in Distillation Column: Weeping happens when the liquid falls through the trays due to insufficient vapor flow, resulting in poor mass transfer.

Column Fouling: When impurities build up inside the column, obstructing the proper flow of liquids and vapors.

Distillation Column Systems

Distillation Column Systems typically include the column itself, a reboiler, a condenser, and related accessories such as pumps and valves. These systems are integrated to provide optimal performance, ensuring efficient separation while maintaining process stability.

Industrial Distillation Column Applications

Industrial Distillation Columns are used across multiple industries, including:

Petrochemical Industry: Separation of crude oil into various fractions such as gasoline, diesel, and kerosene.

Chemical Industry: Purification of solvents, acids, and bases.

Pharmaceutical Industry: Isolation of specific compounds from natural products or synthetic mixtures.

Food and Beverage Industry: Distillation of alcohols and essential oils.

Water Treatment Plants: Purifying water through multi-column distillation.

Goel Impex manufactures high-performance Industrial Distillation Columns that meet the rigorous standards of these industries.

Why Choose Goel Impex for Distillation Column Needs?

Expert Design & Engineering: Our team of experts can help you design the ideal distillation column for your specific process requirements.

High-Quality Materials: We use durable and reliable materials to ensure the longevity and efficiency of our distillation column systems.

Customization: We offer customizable solutions, including multi-column distillation plants and specialized fractional distillation columns, tailored to your operational needs.

Efficient Performance: Optimized for maximum separation efficiency.

Durability & Reliability: Long-lasting and maintenance-friendly.

Comprehensive Support: From initial design to post-installation support, we provide ongoing service to ensure your distillation column operates at peak efficiency.

Goel Impex specializes in providing premium distillation columns for various industrial applications. Whether you need a fractional distillation column, a packed distillation column, or a tray distillation column, we have the right solution for your needs.

Our distillation column is designed for optimal performance, cost-effectiveness, and durability, ensuring your operations run smoothly and efficiently. Contact us today to learn more about how our distillation columns can benefit your processes.