© 2025 Goel Impex.

All Rights Reserved.

Design By : Ads Media Solutions

Random Packings

Random Packings - Metals

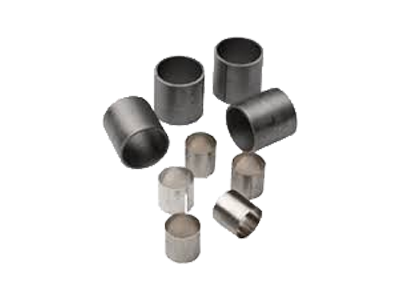

Cylindrical Rings

- Bulk density : 200-900 kg/m3

- Surface area : 90-600 m2 /m3

- NTSM : 1.5-1.8

- High mechanical strength.

- Thickness : : 0.3mm - 1.0mm

P-Rings

- Bulk density : 220-350 kg/m3

- Surface area : 120-500 m2 /m3

- NTSM : 1.8-2.2

- Thickness : 0.3mm - 0.6mm

C-Rings

- Bulk density : 150-250 kg/m3

- Surface area : 110-220 m2 /m3

- NTSM : 2.2-2.5

- Thickness : 0.3mm - 0.8mm

- Low pressure drop, Suits vacuum systems Good liquid distribution, High throughput, Low liquid hold-up.

Saddle Rings

- Bulk density : 120-330 kg/m3

- Surface area : 60-280 m2 /m3

- NTSM : 2.2-2.5

- Thickness : 0.3mm - 0.8mm

- Very low pressure drop, Suits high vacuum application.

- Very low liquid hold-up.

HP Rings

- Bulk density : 190-280 kg/m3

- Surface area : : 90-270 m2 /m3

- NTSM : 1.8-2.2

- Thickness : 0.3mm - 0.6mm

- High capacity, lower pressure drop, high mechanical strength than P-Rings.

N Rings

- Bulk density : 130-180 kg/m3

- NTSM : 1.2-2.5

- Very low pressure drop, Suits high vacuum application.

- Very low liquid hold-up.

Random Packings - Plastics

P-Rings

- MOC : PP, PVDF

- Bulk density : : 55-110 kg/m3

- Surface area : 100-350 m2 / m3

- NTSM : : 1.8-2.5

Saddle Rings

- Bulk density : : 45-75 kg/m3

- Surface area : : 85-230 m2 / m3

- NTSM : 2.0-2.5

Random Packings - Ceramics

Saddle Rings

- Bulk density : 590-720 kg/m3

- Surface area : 100-522 m2 / m3

- NTSM : 1.8-2.6

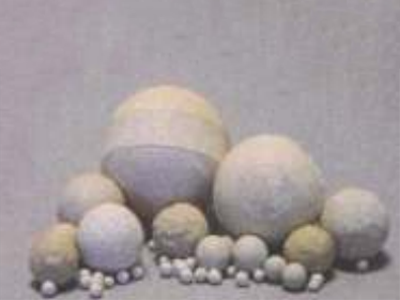

Balls

- Bulk density : 1300-1400 kg/m3

- Surface area : 65-420 m m2 / m3

- NTSM : 0.8-1.5

P-Rings

- Bulk density : 500-650 kg/m3

- Surface area : 55-220 m2 / m3

- NTSM : 1.4-1.8

Cylindrical Rings

- Bulk density : 500-840 kg/m3

- Surface area : 44-350 m m2 / m3

- NTSM : 1.4-1.7