Efficient gas absorption depends on the following:

- Intimate contact

- Efficient Heat Transfer

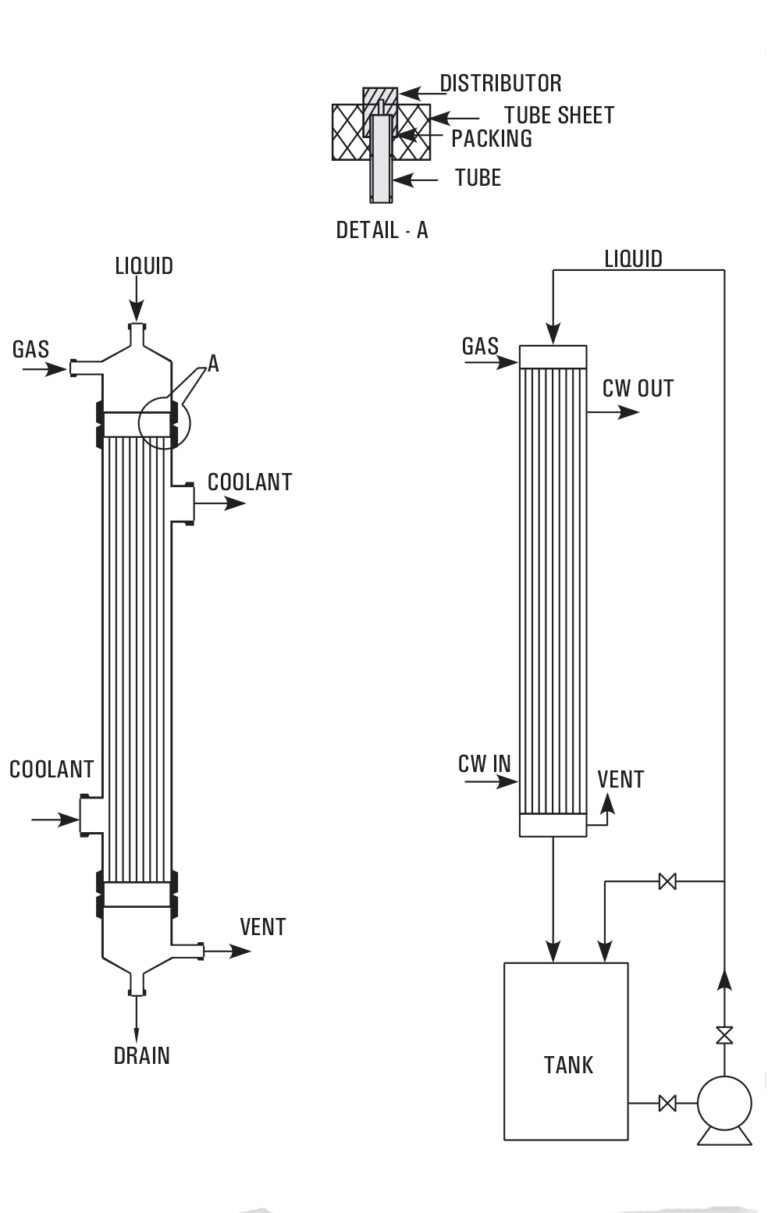

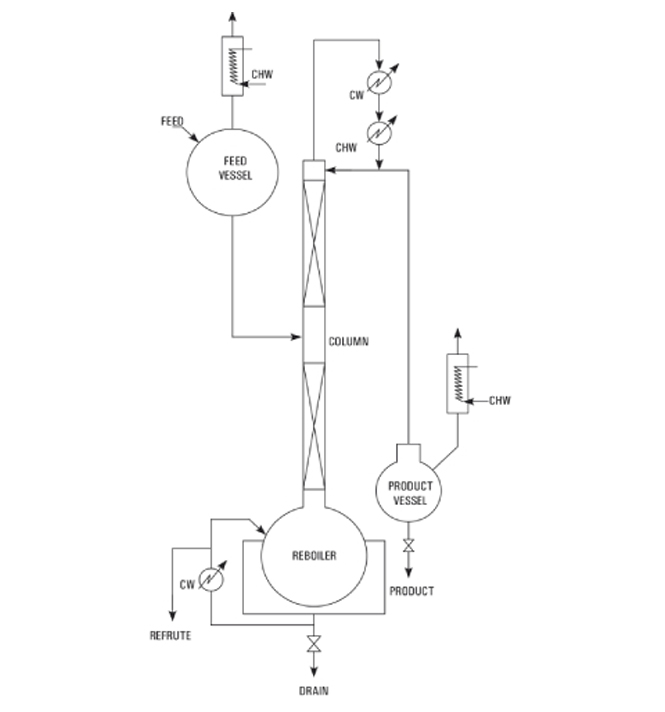

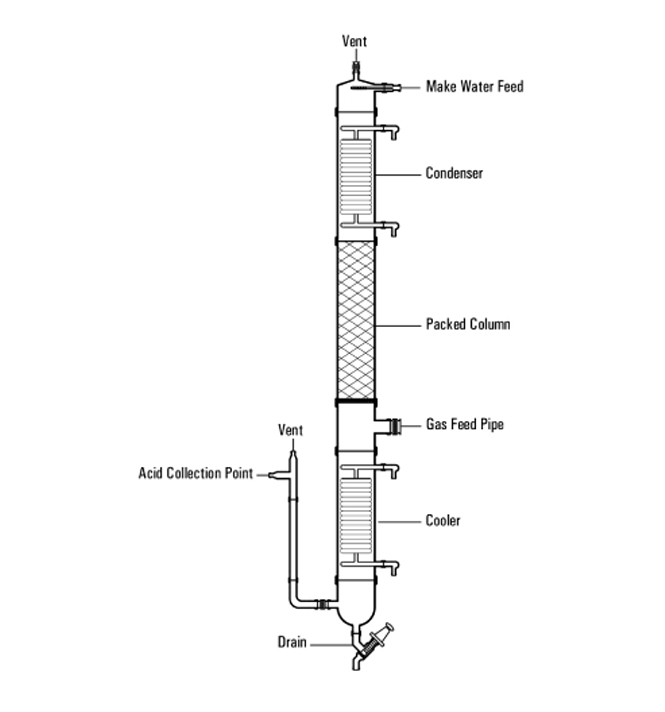

This is achieved in a Falling Film Absorber which is essentially a shell & tube heat exchanger in which both gas to be absorbed and absorbing liquid flow co-currently downward with extraction of heat by circulation of coolant in the shell. The abssorbing liquid is circulated through a tank till desired concentration is achieved. The liquid flows at such a rate that the tubes do not flow full of the liquid but instead, descends by gravity along the inner walls of the tubes as a thin film. Obviously, this produces a much greater linear velocity for a giver rate flow than could be obtained if the tube flowed full.

The equipment works as a number of water cooled-wall columns in parallel and each tube is provided with distribution system on top to effect uniform distribution of both liquid and gas and also formation of a thin liquid film on the inner surface of the tube.

SALIENT FEATURES

- The heat of absorption is continuously removed. This ensures better absorption and product concentration as compared with conventional packed tower

- Low residence time and operating temperature ideally suited to heat sensitive materials.

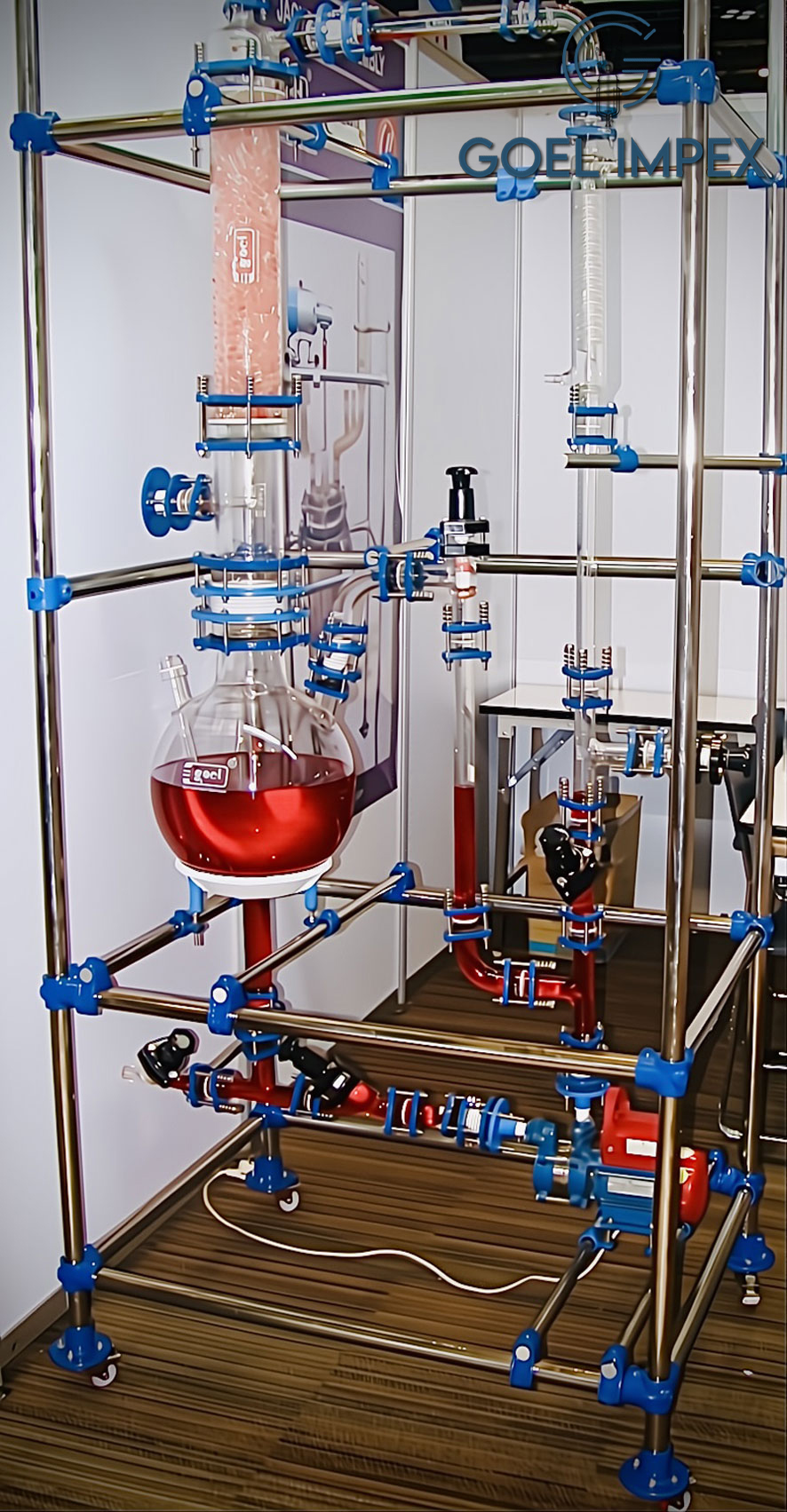

- Borosilicate glass and PTFE contact parts ensure corrosion/ contamination free operation

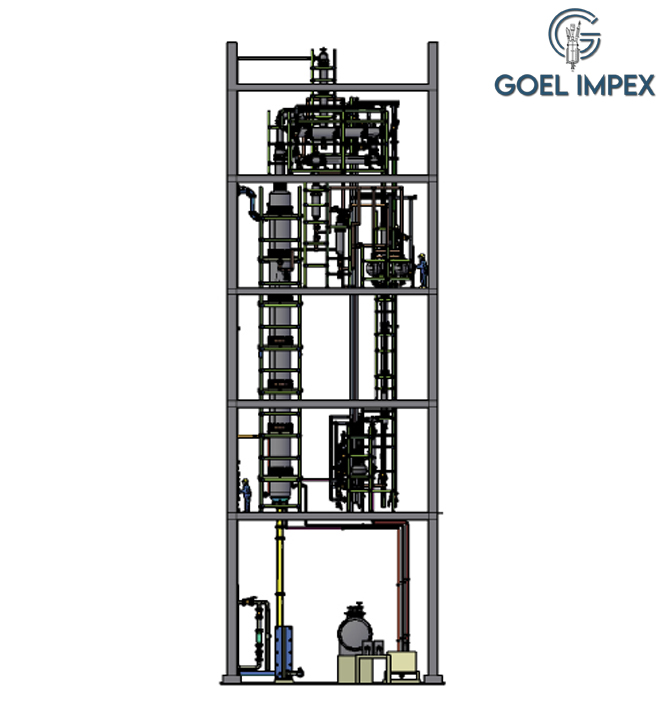

- Both standard and custom built units are available.

- Capable of operating from zero to maximum gas flow rate.

- Ease of installation due to light weight.

- Trouble free and consistent performance with minimal attention.

- Wide application e.g. HCl, HBr, NH , SO , H S, Br etc

- Less cost.

- Negligible pressure drop compared to conventional columns.

- Compact design Sleek and slender

- Both heat and mass transfer operations are incorporated in a single equipment.

- Very high heat transfer coefficient as the liquid falls instead of flowing.

- Scaling of process fluid is minimal due to high velocity and ease of cleaning by simple acid circulation.

- Hot conditions are eliminated at all stages namely pipe, tanks and pumps etc

LIMITATIONS

- Not recommended for gases containing high proportion of inert (insoluble).

- Not applicable if the gases are not highly soluble

SPECIFICATIONS

|

Sr. No. |

Nominal Size (mm) |

Absorber Area (m2) |

No.of Tubes/ Tube OD (mm) |

Max.Gas Absorption Rate (Pure HCl) * (kg/hr) |

Max.Acid Prod. Rate (As 30 % HCl) (kg/hr) * |

Height (m) |

|

1. |

80 |

1.00 |

4/ 20 |

30 |

100 |

4400 |

|

2. |

100 |

1.76 |

7/ 20 |

60 |

200 |

4500 |

|

3. |

150 |

4.80 |

19/ 20 |

150 |

500 |

4600 |

|

4. |

225 |

7.80 |

31/ 20 |

250 |

833 |

4920 |

|

5 |

300 |

15.30 |

61/ 20 |

500 |

1667 |

5050 |

|

6 |

400 |

36.00 |

143/ 20 |

1175 |

3917 |

5300 |

|

7 |

450 |

47.00 |

187/ 20 |

1500 |

5000 |

5700 |

|

8 |

600 |

84.00 |

333/ 20 |

2700 |

9000 |

5800 |