Goel Impex offers high-quality pilot plant systems designed to support process development, optimization, and scale-up for various industries. Our advanced pilot plant solutions provide a bridge between laboratory research and full-scale production, ensuring smooth transitions in chemical, pharmaceutical, and industrial glassware applications.

Goel Impex offers a versatile pilot plant designed for chemical and pharmaceutical industries to support process development, scale-up, process simulation, and kilo-scale cGMP production in both batch and semi-batch operations.

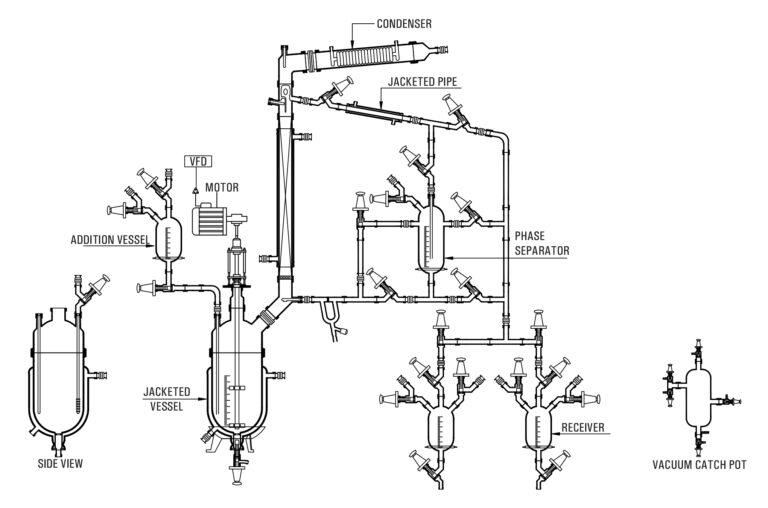

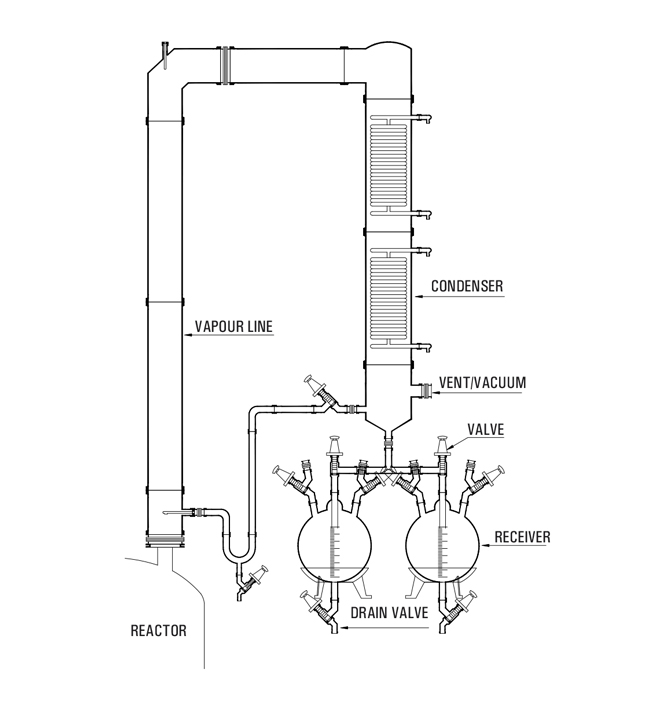

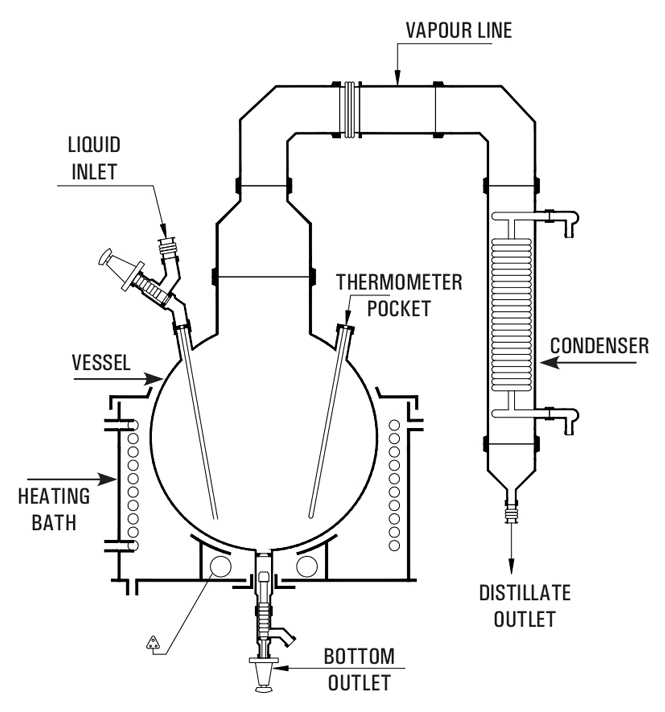

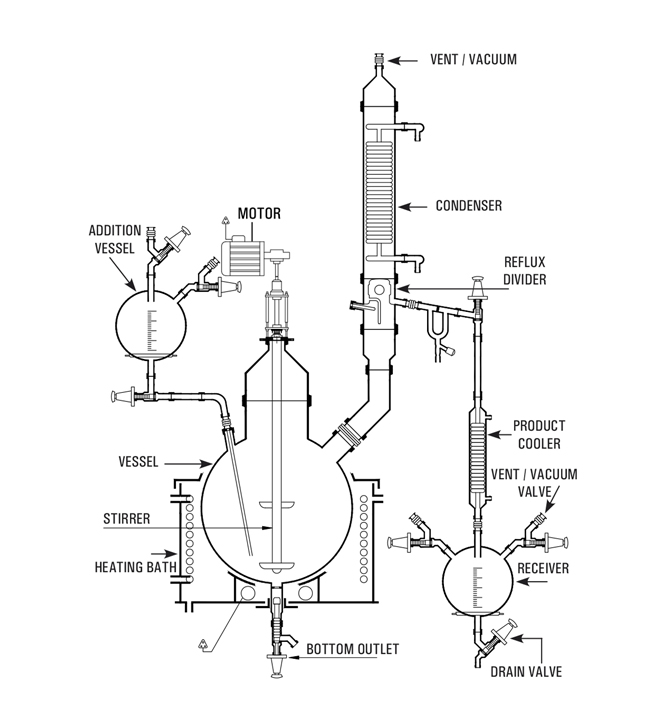

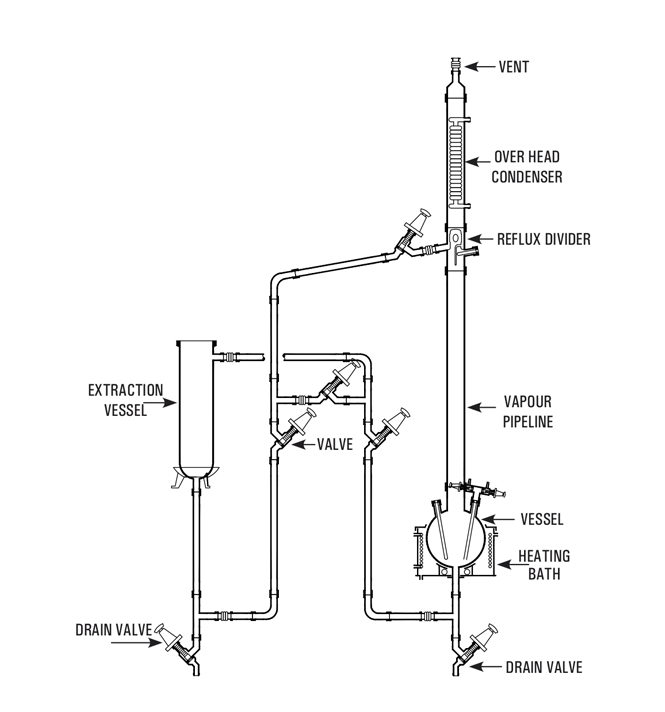

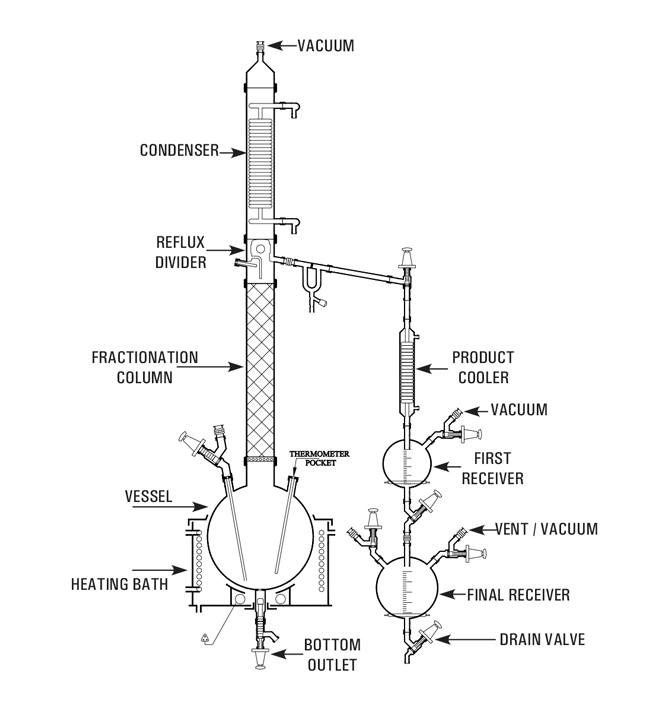

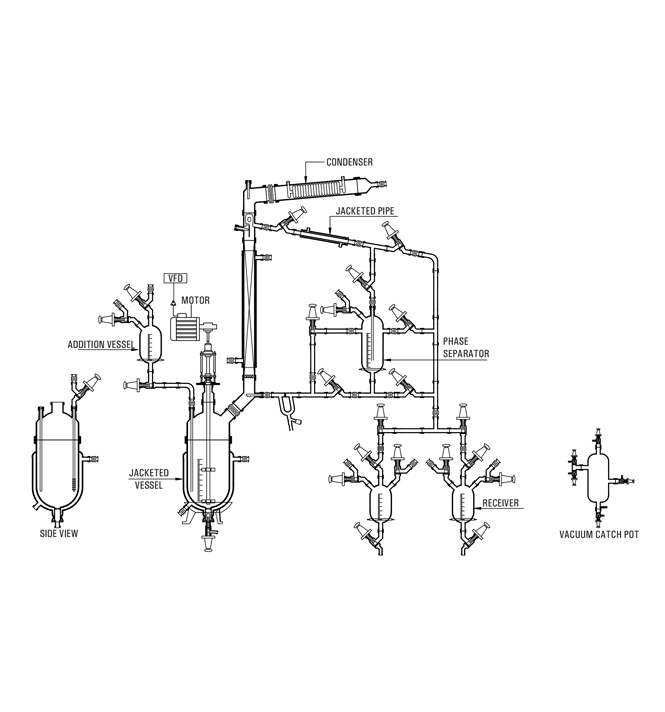

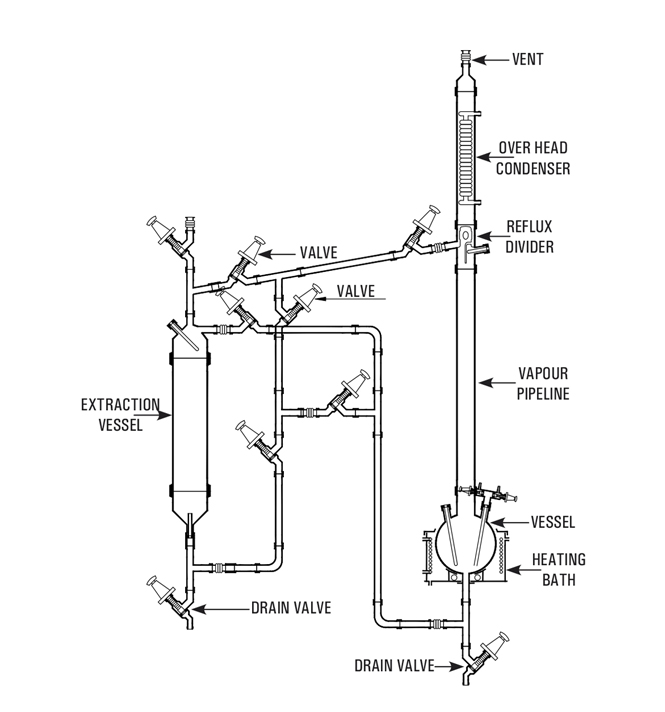

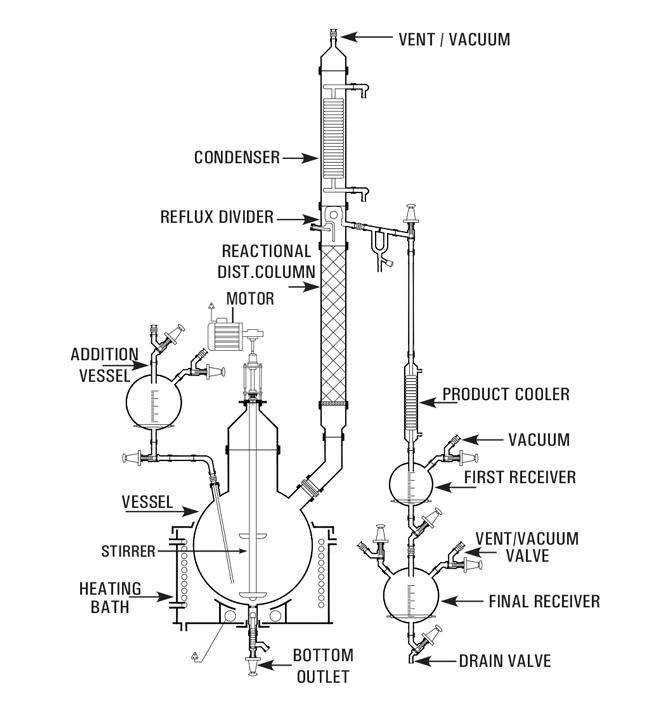

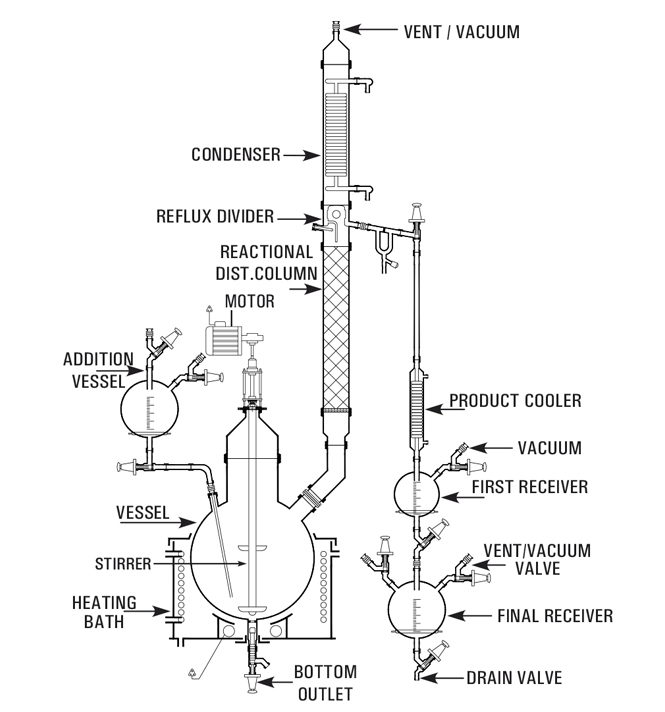

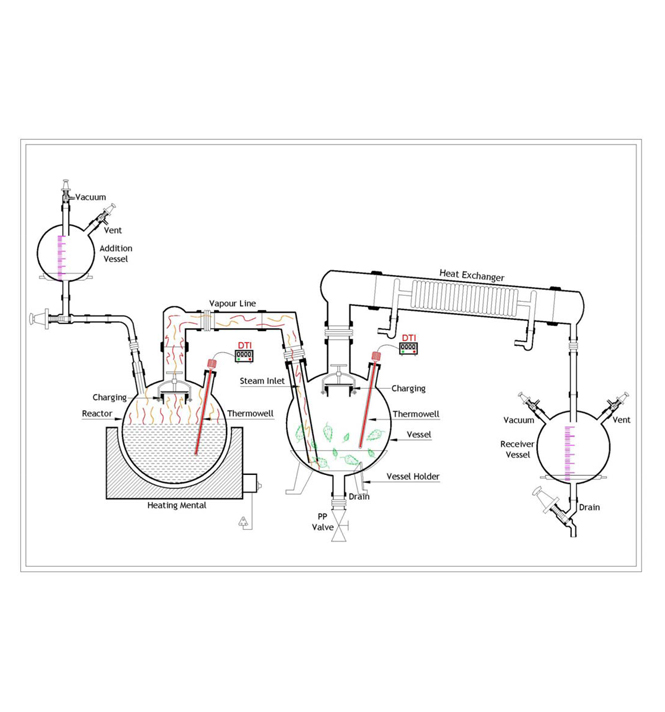

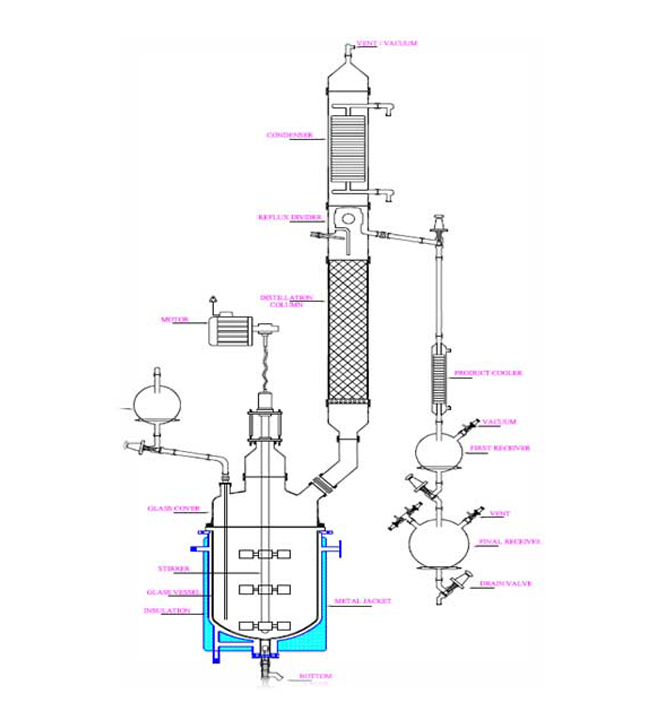

Our pilot plant for chemical processing is engineered for seamless operations, including solid charging, liquid charging, reaction, heating/cooling, rectification, and auto/manual reflux arrangements.

Designed for maximum flexibility, the multipurpose pilot plant can be easily modified and customized to meet specific process requirements, ensuring efficient and scalable production.

Upgrade your process development and scale-up with a high-performance pilot plant from Goel Impex.

Pilot Plant Available with:

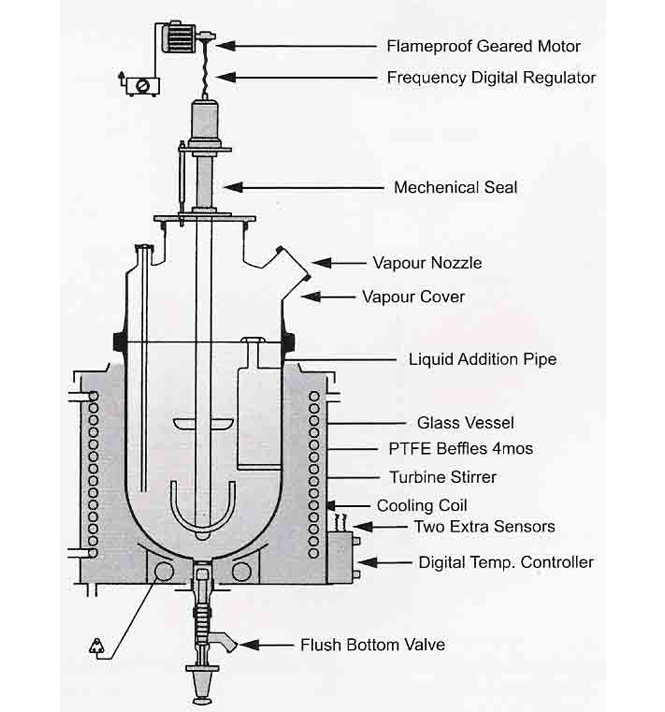

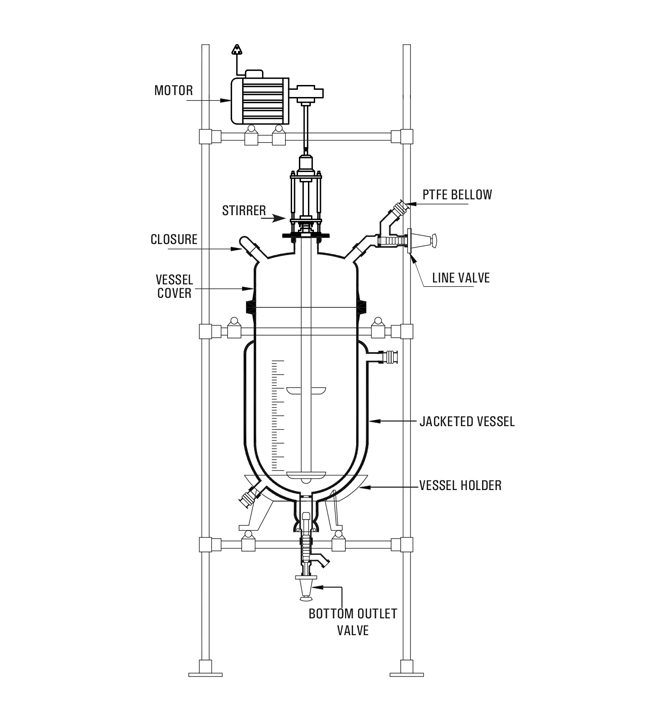

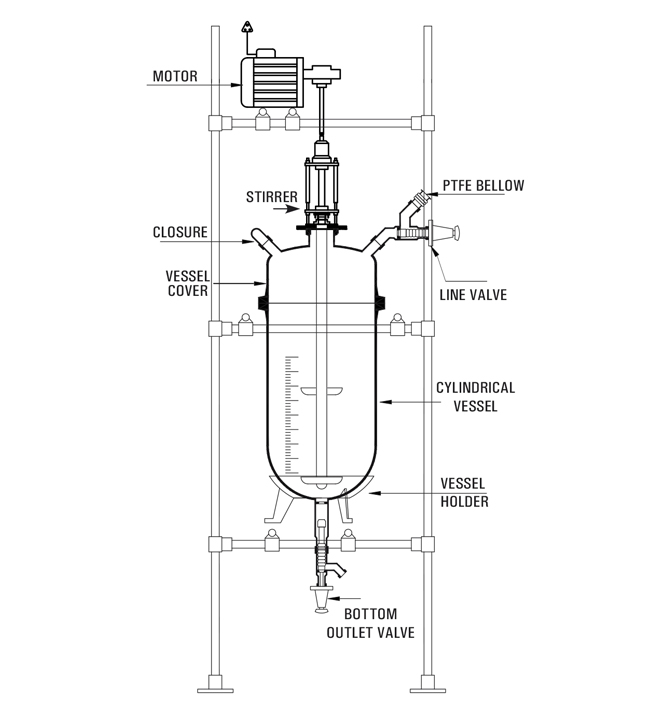

- Jacketed Glass Reactor / Cylindrical Glass Reactor / Spherical Glass Reactor with Oil Heating & Cooling Bath for precise temperature control.

- Multipurpose Glass Distillation Overhead for efficient separation and purification.

- Stainless Steel, MS Epoxy Coated, or MS Painted for enhanced stability and longevity.

- Available in Flame-Proof, Non-Flame-Proof, cGMP, and Non-GMP Models to suit diverse industrial requirements.

- Superior Corrosion Resistance ensures longevity and reliability in chemical processing.

- Advanced Temperature Controller for precise monitoring and control.

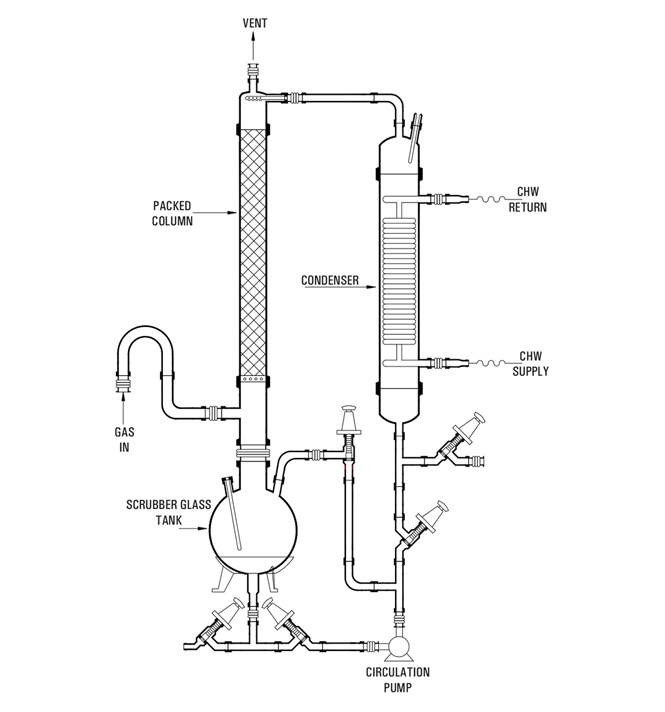

- Supports Gas Purging, Solid Charging, and Multi-Liquid Addition for versatile chemical processes.

- Vacuum & Exhaust Piping for optimized system performance.

- Additional Feeders & Receivers for seamless material handling.

- Solid Feeding System for efficient processing and scalability.

|

Unit |

Reduction |

Bath KW |

Addition |

Vapour |

Condenser |

Cooler |

Receiver Size |

|

MPU 20 |

20 L |

4.5 |

2 L |

80 DN |

0.35 |

0.10 |

2L, 5L |

|

MPU 50 |

50 L |

6.0 |

5 L |

100 DN |

0.50 |

0.20 |

5L, 10L |

|

MPU 100 |

100 L |

9.0 |

10 L |

150 DN |

1.50 |

0.35 |

10L, 20L |

|

MPU 200 |

200 L |

12.0 |

20 L |

150 DL |

1.50 |

0.35 |

10L, 20L |

|

MPU 300 |

300 L |

16.0 |

20 L |

225 DL |

2.50 |

0.50 |

20L, 20L |

*marked items are available fast.

What is a Pilot Plant?

A multipurpose pilot plant is a small-scale processing unit that replicates industrial manufacturing processes. It allows companies to test new formulations, optimize production techniques, and assess scalability before committing to large-scale production. Pilot plants play a crucial role in industries such as pharmaceuticals, chemicals, petrochemicals, and food processing.

Objectives of a Pilot Plant

The primary objectives of a pilot plant include:

Process Development: Fine-tuning chemical and industrial processes to achieve optimal efficiency.

Scale-Up Testing: Evaluating and adjusting laboratory results for large-scale applications.

Cost Reduction: Identifying potential savings in raw materials, energy, and production processes.

Product Quality Assurance: Ensuring consistency and compliance with industry standards.

Risk Mitigation: Detecting operational and technical challenges before full-scale production.

Technology Transfer: Facilitating the smooth transition from R&D to full-scale production.

Importance of a Pilot Plant

The importance of a pilot plant cannot be overstated. It serves as a crucial step in product development, offering benefits such as:

Reducing production risks by testing processes before full-scale implementation.

Improving efficiency by identifying process bottlenecks.

Increasing product development through controlled testing environments.

Complying with industry regulations by validating processes before large-scale production.

Train personnel in real production conditions.

Pilot Plant Scale-Up Techniques

Effective pilot plant scale-up techniques are crucial for ensuring seamless production transitions. At Goel Impex, we specialize in methodologies that include:

Geometric Scaling: Maintaining the proportional design between lab and large-scale processes.

Dynamic Similarity: Ensuring fluid flow patterns remain consistent across scales.

Chemical Kinetic Analysis: Assessing reaction rates and optimizing process parameters.

Material Flow Optimization: Improving the transfer of raw materials to maximize efficiency.

Energy Balance Consideration: Ensuring heat transfer and energy consumption match expected levels.

Thermal Control Strategies: Implementing temperature management solutions for better reaction control.

Process Automation Integration: Implementing automation solutions for efficiency and reproducibility.

Pilot Plant Solutions

At Goel Impex, we provide customized pilot plant solutions customized to meet the specific needs of various industries. Our expertise includes:

Pilot Plant System Design: Optimized configurations for diverse applications.

Pilot Plant Equipment: High-quality reactors, distillation units, filtration systems, and more.

Pilot Plant Specialists: Expert guidance for installation, operation, and process optimization.

Pilot Plant Systems

Goel Impex provides a wide range of pilot plant systems customized to meet industrial requirements. Our pilot plant specialists offer customized solutions for:

Chemical Processing: Ensuring precision and efficiency in chemical reactions.

Pharmaceutical Production: Assisting in drug development and formulation testing.

Glassware Engineering: Developing innovative industrial glass solutions for multiple applications.

Pilot Plant Equipment

Our pilot plant equipment is designed for durability, efficiency, and compliance with industry standards. We offer:

Reactor Systems : Suitable for batch and continuous operations.

Distillation Units: For high-purity separation processes.

Evaporation Systems: Optimized for efficient solvent removal.

Filtration & Drying Equipment: Improving process efficiency.

Why Choose Goel Impex for Pilot Plant Solutions?

As pilot plant specialists, we provide end-to-end support, from design to commissioning, ensuring seamless process development. With our expertise in pilot plant systems, we help industries achieve precision, scalability, and cost efficiency.

High-Quality Materials: Durable, corrosion-resistant industrial glassware.

Industry Expertise: Decades of experience in designing and manufacturing high-quality.

Advanced Technology: Advanced engineering solutions for process scale-up and optimization.

Customization Solutions: Customized pilot plant equipment to suit specific industrial needs.

Regulatory Compliance: Systems designed to meet international safety and quality standards.

Comprehensive Support: Expert guidance from concept development to commercial production.

Whether you need a multipurpose pilot plant system for research, development, or full-scale production, Goel Impex has the right solution for you. Contact us today to discuss your specific requirements and explore our advanced pilot plant solutions.