The Glass Distillation Apparatus is a fundamental equipment used in laboratories to separate liquid mixtures using steam distillation apparatus. This apparatus, which consists of a glassware assembly that includes a boiling flask, condenser, and receiving flask, works by heating the mixture to its boiling point, resulting in vaporization.

The vapor passes through the condenser, cooling and returning to liquid form before collecting in the receiving flask. The apparatus's translucent glass components enable a clear sight of the distillation process, assuring precise and accurate component separation.

The Glass distillation apparatus is widely used in chemistry, biology, and research contexts to enable substance purification, essential oil extraction, and volatile chemical characterization. Its versatility and dependability make it ideal for laboratory investigations and industrial applications.

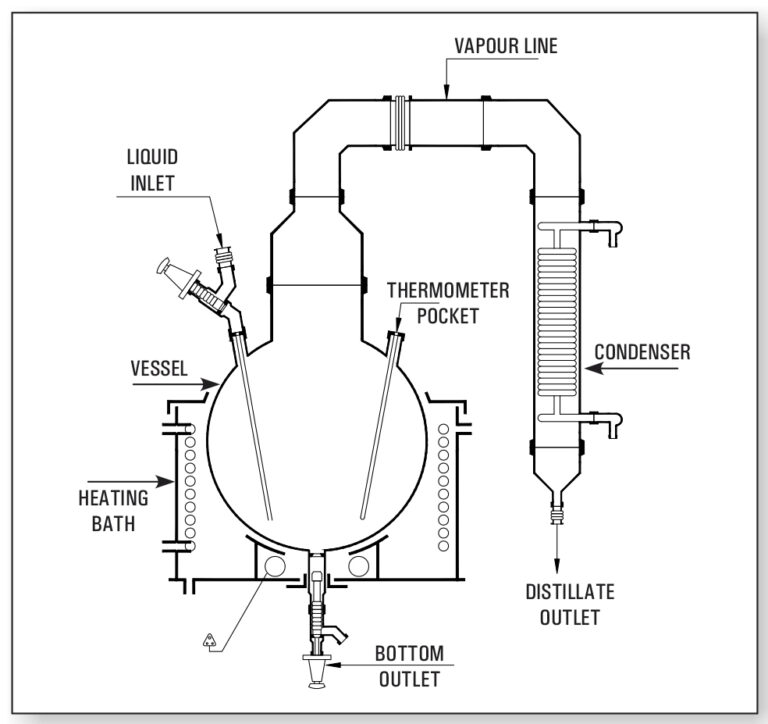

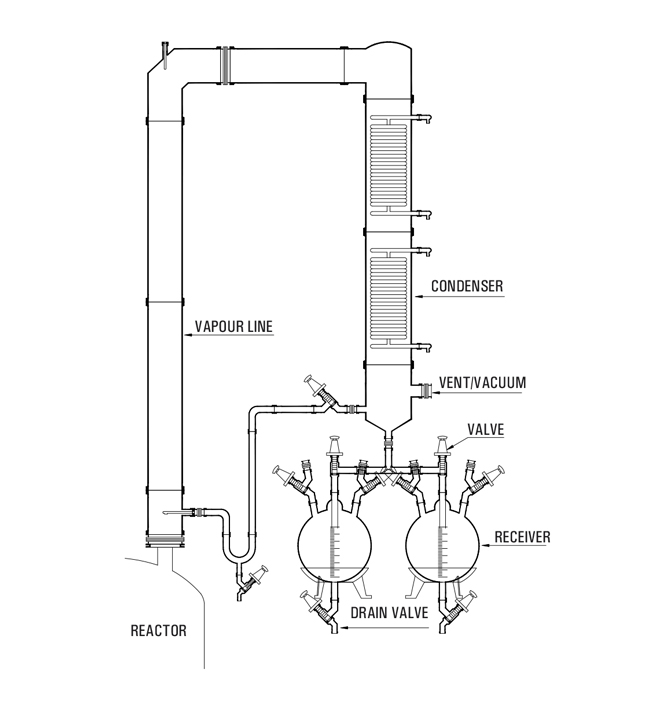

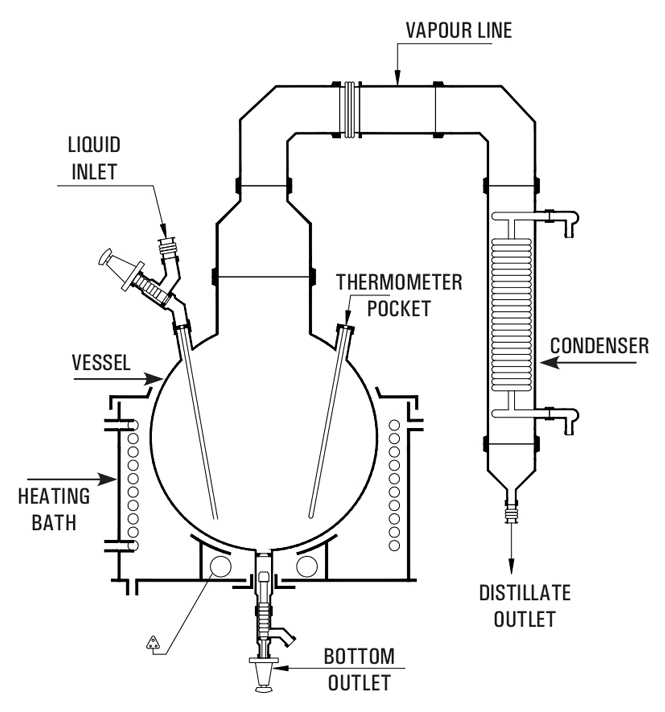

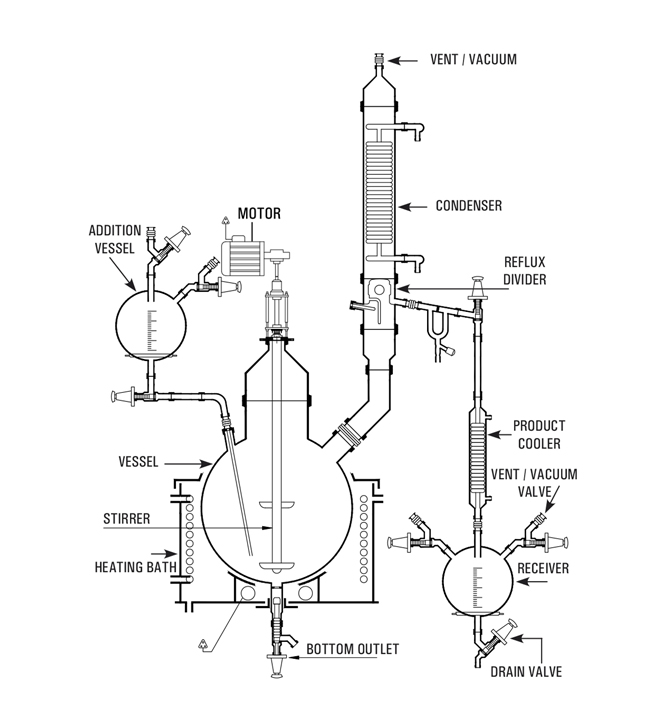

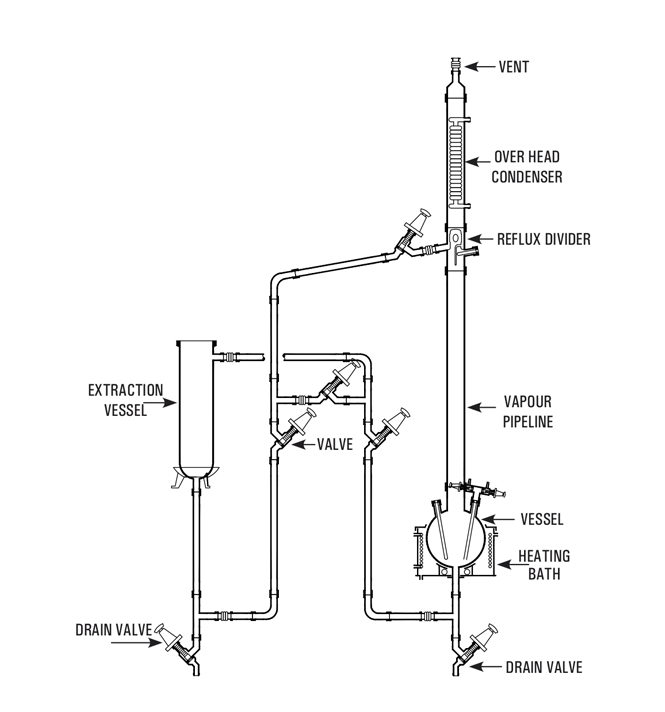

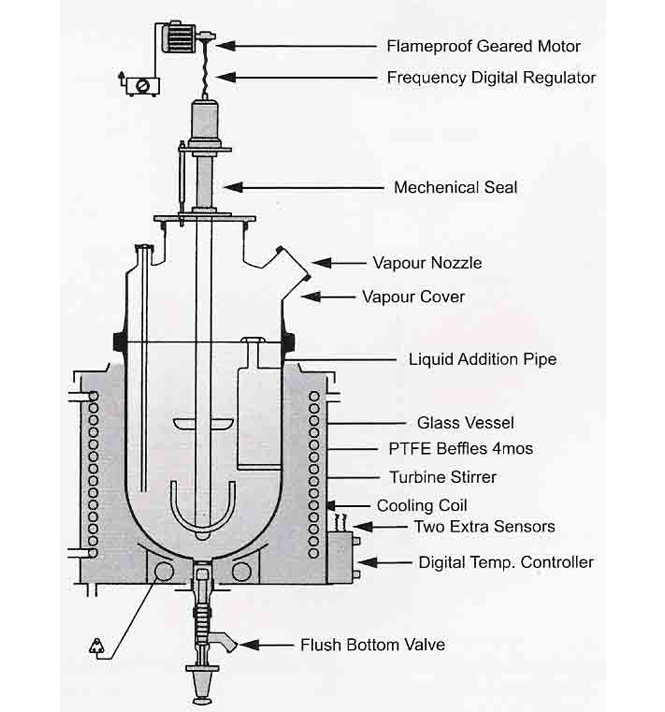

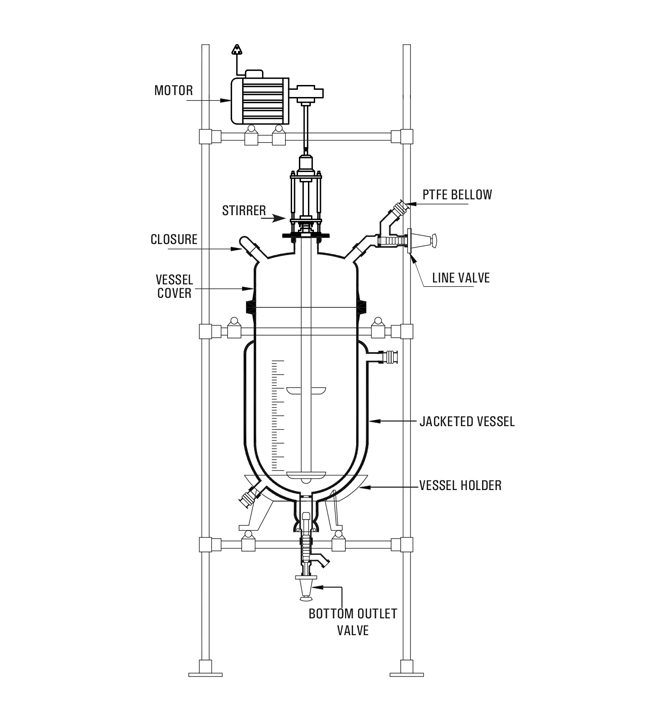

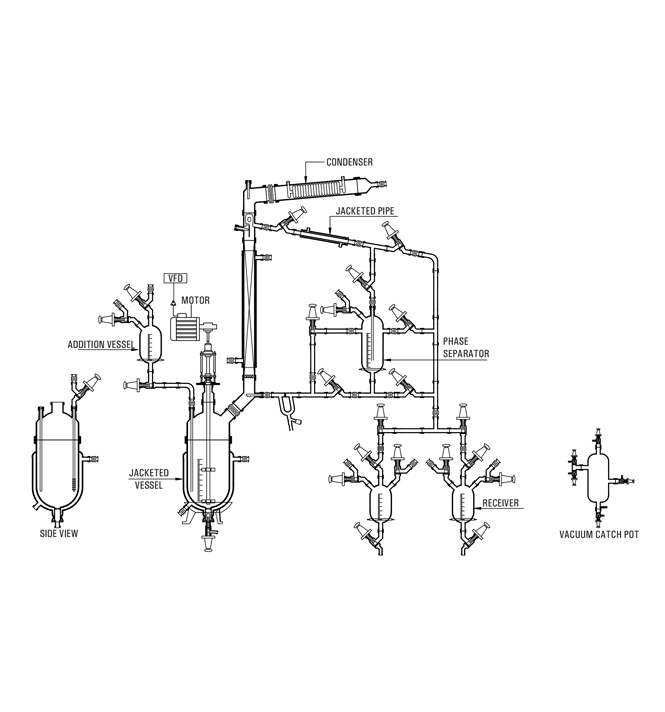

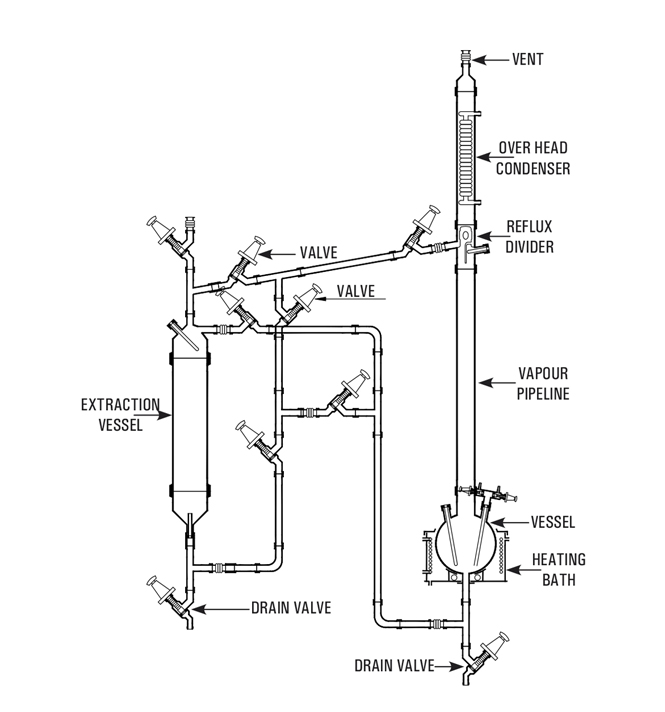

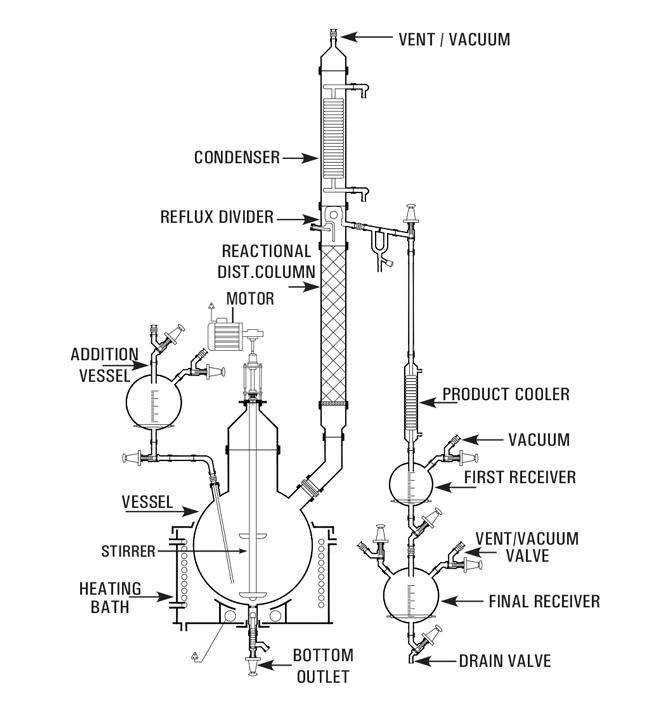

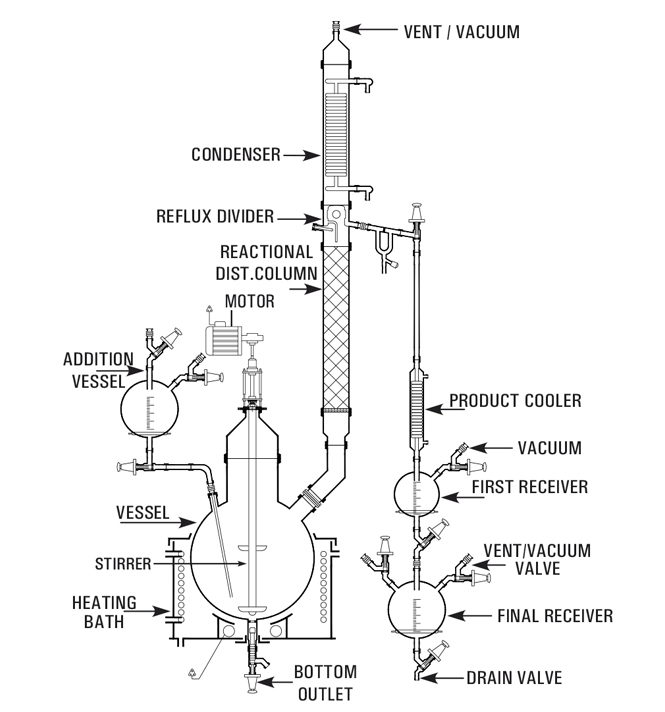

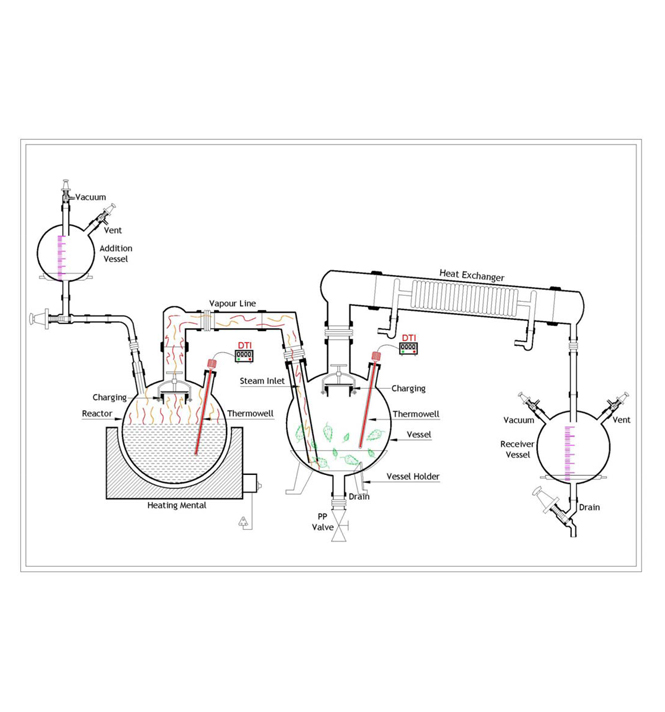

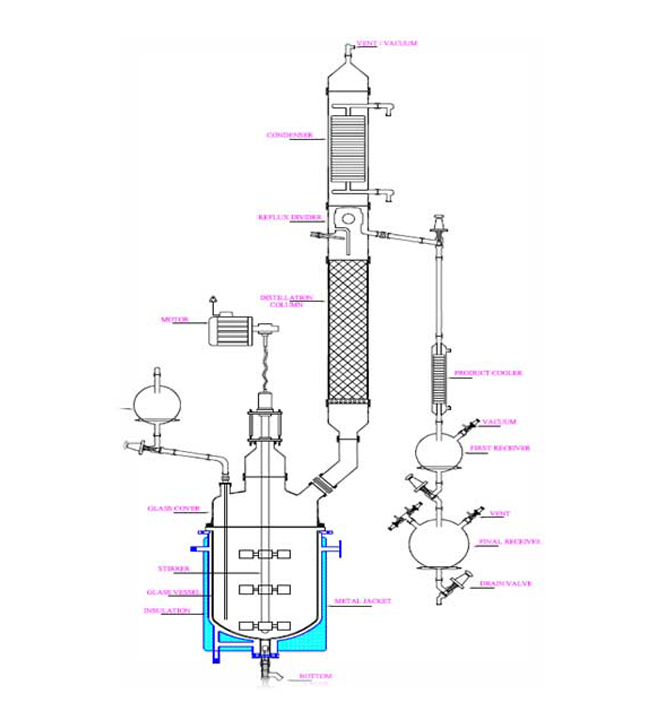

At Goel Impex, our Distillation Apparatus features a vessel integrated into a heating bath paired with a condenser to condense vapors efficiently.

A receiver with a drain valve can also be incorporated to collect the condensate easily.

Distillation apparatus are available in vessel sizes of 20, 50, 100, 200, and 300 L and may operate under air pressure and full vacuum.

All wetted parts comprise borosilicate glass or PTFE to ensure optimal reactant compatibility.

|

Unit Cat. Ref. |

Reactor Capacity |

Bath KW |

Vapour Line |

Condenser M2 |

|

SDU20 |

20 L |

4.5 |

80 DN |

0.35 |

|

SDU50 |

50 L |

6.0 |

100 DN |

0.50 |

|

SDU100 |

100 L |

9.0 |

150 DN |

1.50 |

|

SDU200 |

200 L |

12.0 |

150 DN |

1.50 |

|

SDU300 |

300 L |

16.0 |

225 DN |

2.50 |

About Distillation Apparatus

At Goel Impex, we pride ourselves on providing top-quality industrial glassware, and our Glass Distillation Apparatus stands out for its efficiency, reliability, and durability. Whether you are conducting scientific research, pharmaceutical development, or chemical analysis, our distillation apparatus is designed to meet your precise needs.

Goel Impex offers a premium Distillation Apparatus designed for efficient separation and purification of liquids in laboratories and industrial settings. Our Glass Distillation Apparatus ensures high thermal and chemical resistance, making it ideal for various distillation processes.

What is a Distillation Apparatus?

A Distillation Apparatus is a specialized setup used for purifying and separating liquids based on differences in boiling points. It plays a crucial role in industries such as pharmaceuticals, petrochemicals, and research laboratories.

Types of Distillation Apparatuses

We provide a range of distillation apparatuses to suit different applications:

1. Simple Distillation Apparatus

A Simple Distillation Apparatus is used when separating liquids with significant differences in boiling points. It consists of a heating source, boiling flask, condenser, and receiving flask, making it suitable for basic purification.

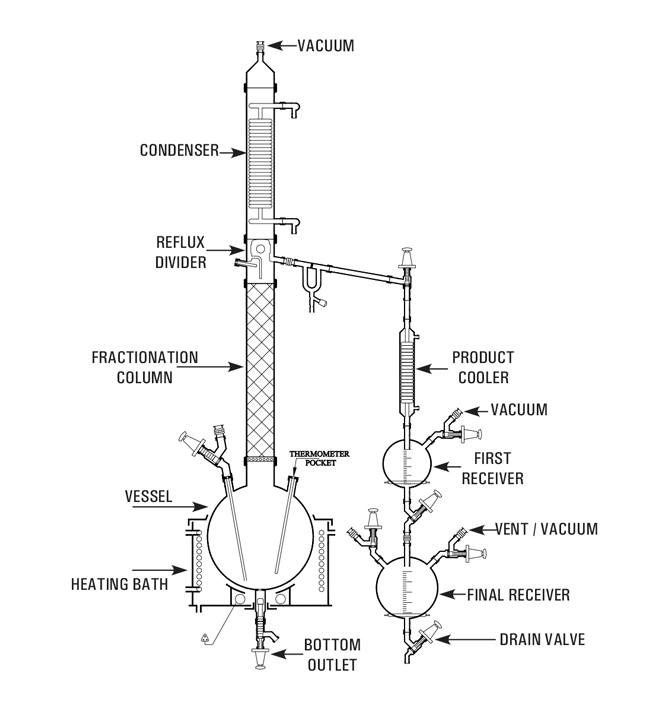

2. Fractional Distillation Apparatus

The Fractional Distillation Apparatus is used for separating liquid mixtures with closer boiling points. It includes a fractionating column that increases the efficiency of separation, commonly used in the petrochemical and alcohol industries.

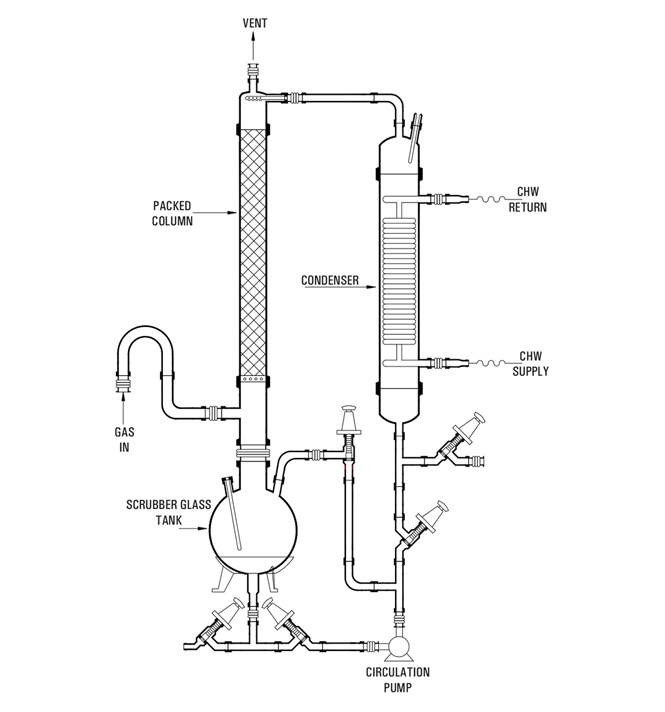

3. Steam Distillation Apparatus

A Steam Distillation Apparatus is used for extracting essential oils and heat-sensitive compounds. By introducing steam, volatile components can be separated without decomposition.

4. Water Distillation Apparatus

A Water Distillation Apparatus is designed to purify water by removing impurities and contaminants. This setup is widely used in medical, chemical, and research laboratories.

5. Double Distillation Apparatus

For ultra-pure distillation, a Double Distillation Apparatus is used. It passes the liquid through two distillation cycles, ensuring high purity in applications such as pharmaceutical and biotechnology research.

6. Laboratory Distillation Apparatus

Our Laboratory Distillation Apparatus is designed for academic and industrial research. It is available in multiple configurations for small-scale experiments and pilot-scale operations.

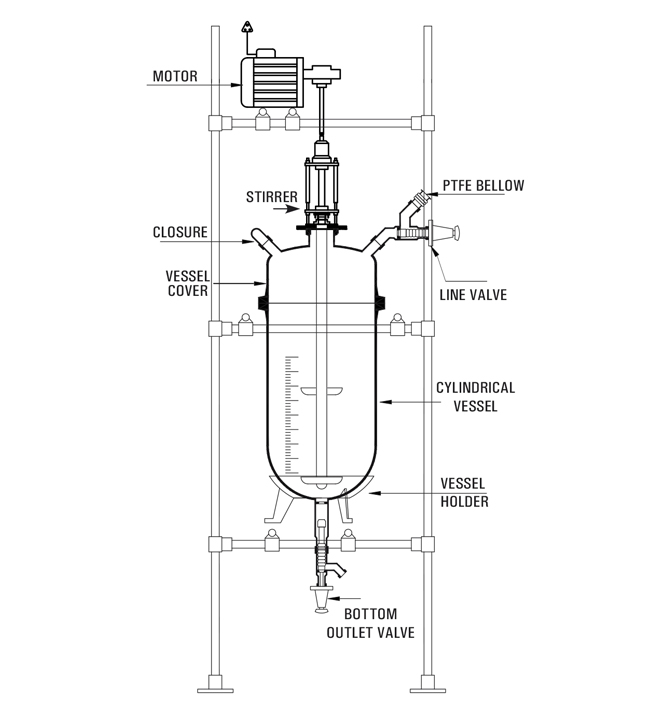

Distillation Apparatus Diagram & Components

A standard distillation apparatus diagram includes the following key components:

Boiling Flask: Holds the liquid to be distilled.

Distillation Flask: Heats the liquid mixture.

Heat Source: Provides controlled heating for vaporization.

Thermometer: Monitors temperature for precise control.

Fractionating Column: Improves separation in fractional distillation apparatus.

Condenser: Cools and condenses vapor back into liquid form.

Receiver Flask: Collects the distilled liquid.

Support Stand & Clamps: Ensure stability and secure connections.

Why Choose Goel Impex Distillation Apparatus?

High-Quality Borosilicate Glass: Ensures durability and chemical resistance.

Precision Engineering: Designed for optimal efficiency and performance.

Customizable Solutions: Available in different sizes and configurations.

Durability & Safety: Designed to withstand high temperatures and prolonged use.

Global Compliance: Manufactured to meet international quality standards.

Trusted by Industries: Used in chemical, pharmaceutical, and research applications.

Applications of Distillation Apparatus

Pharmaceutical Industry: Purification of solvents and drug synthesis.

Chemical Laboratories: Separation of organic and inorganic compounds.

Essential Oil Extraction: Steam distillation for fragrance and aromatherapy.

Water Purification: Production of high-purity distilled water.

Research & Development: Advanced experimental setups for scientific studies.

Educational Institutions: Used for experiments and research in schools and universities.

Petroleum & Refineries: Separation of crude oil components.

Order Your Glass Distillation Apparatus Today!

Goel Impex is your trusted manufacturer of distillation apparatuses. Whether you need a simple distillation apparatus, fractional distillation apparatus, or steam distillation apparatus, we have the right solution for you.

Improve your laboratory or industrial setup with our premium distillation apparatuses. Contact Goel Impex for expert guidance, product customization, and competitive pricing.