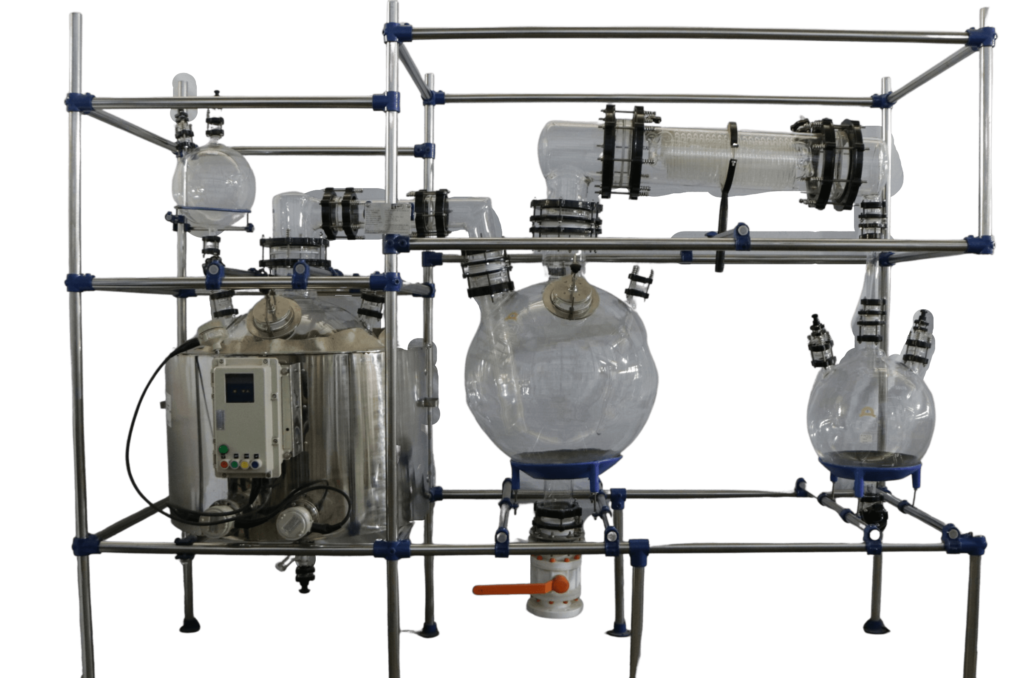

Essential oil distillation is a process used to extract essential oils from plants. These oils capture the plant’s scent and therapeutic properties, making them highly valuable in aromatherapy, perfumery, and various industrial applications. Our advanced distillation equipment ensures you achieve the highest quality and purity in your essential oils.

What is Essential Oil Distillation?

Essential oils can be extracted from various plants, including lavender, eucalyptus, peppermint, and citrus, for use in aromatherapy, cosmetics, and natural medicines. These vapors are then condensed and collected, yielding pure, substantial extracts rich in aroma and health benefits.

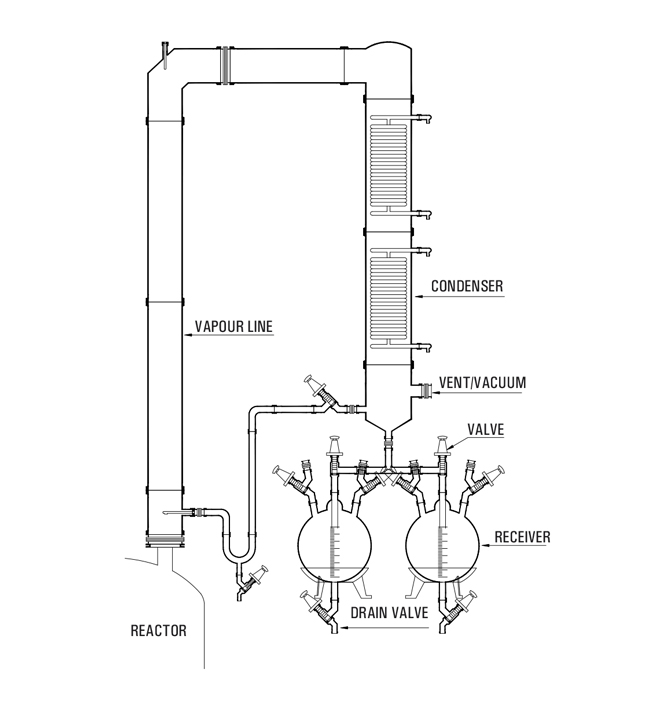

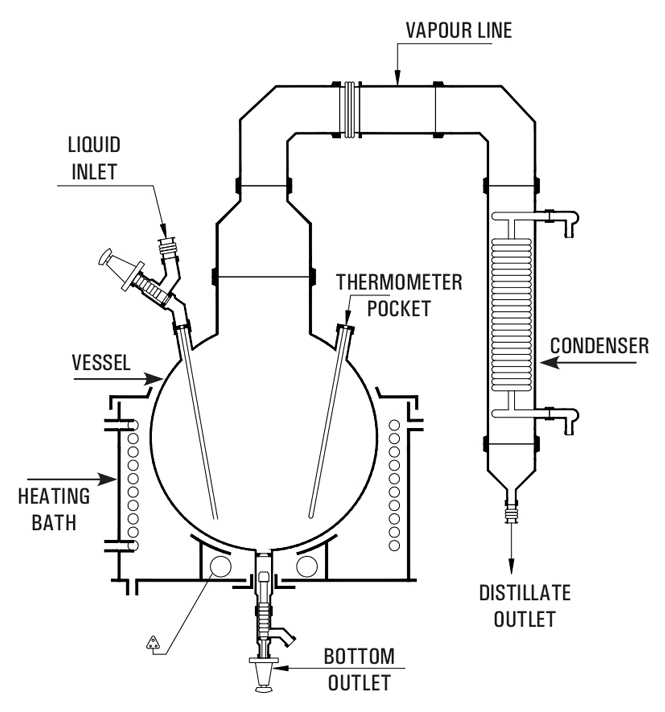

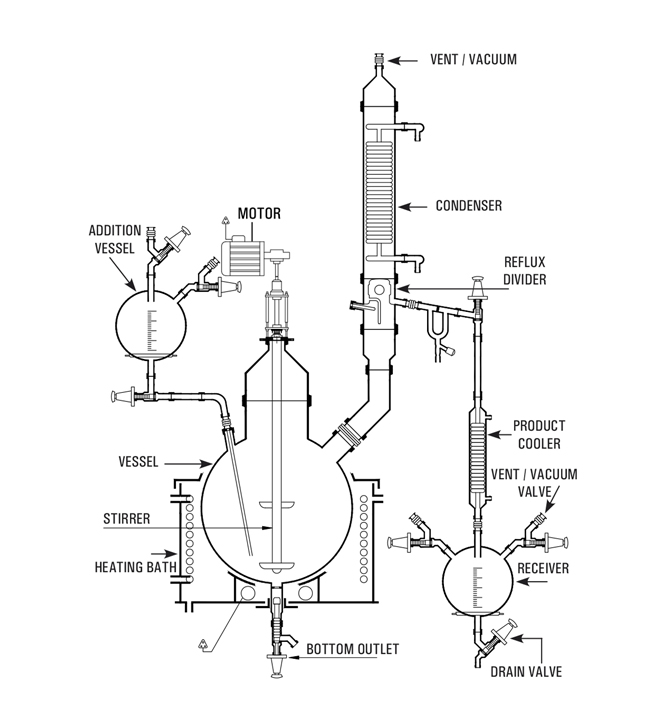

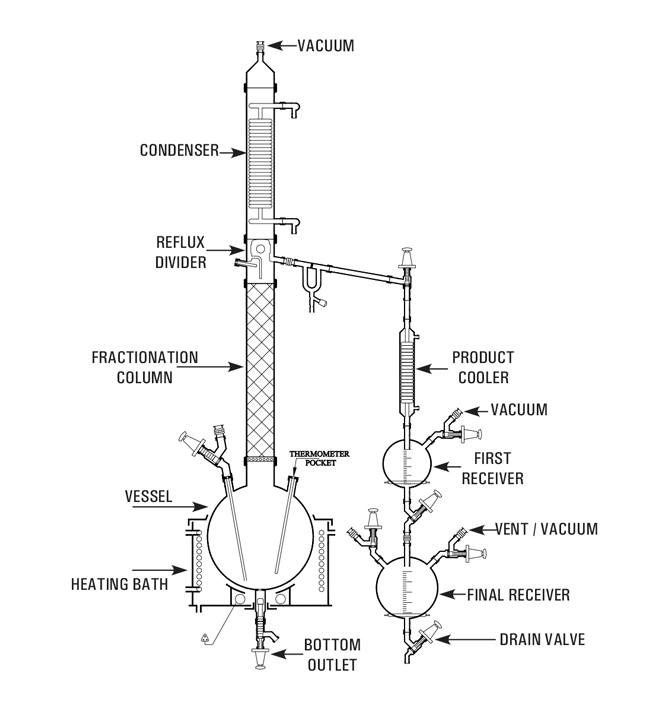

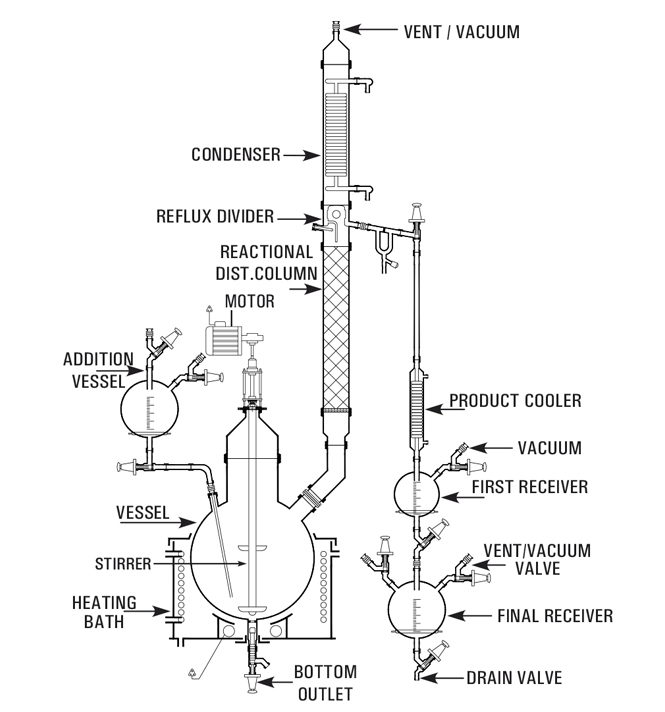

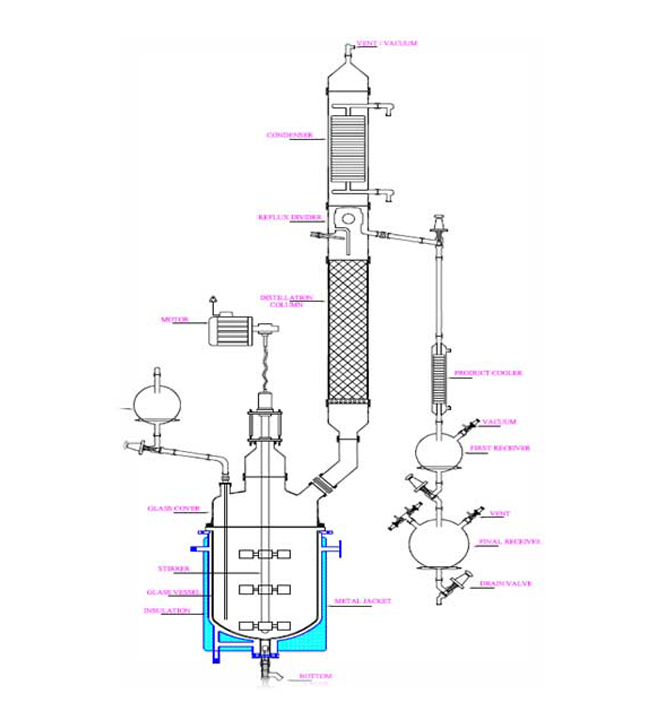

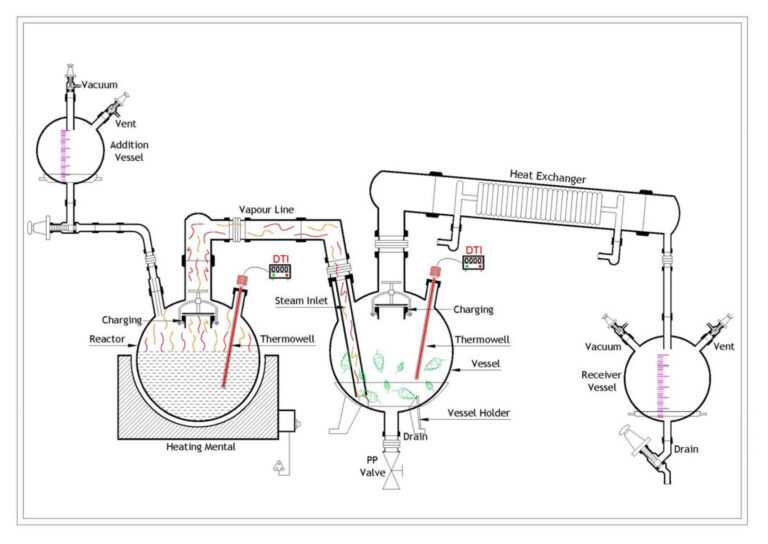

Essential oil distillation captures the essence of nature to produce fragrant and potent oils valued for their holistic effects. Essential oils are generally extracted by distillation, often using steam. We provide two modes through which one can produce essential oils: a Steam Distillation Unit and a Vacuum Distillation Unit.

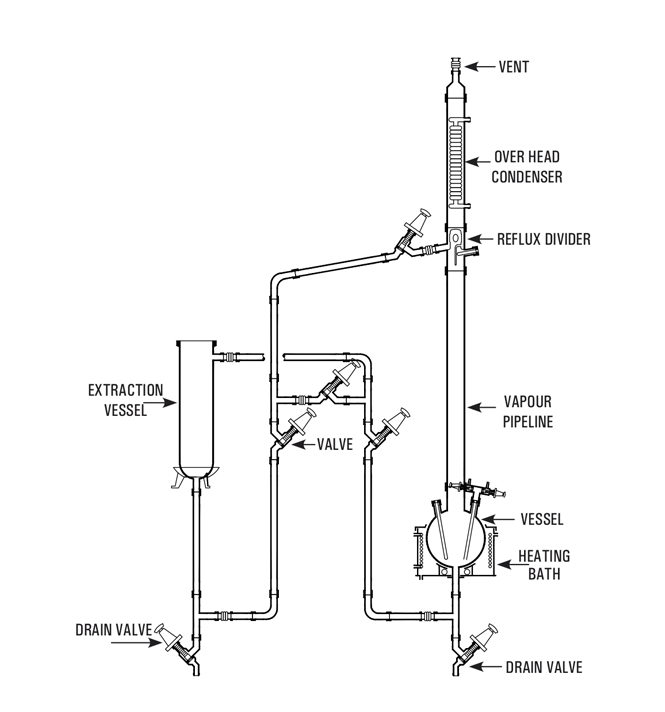

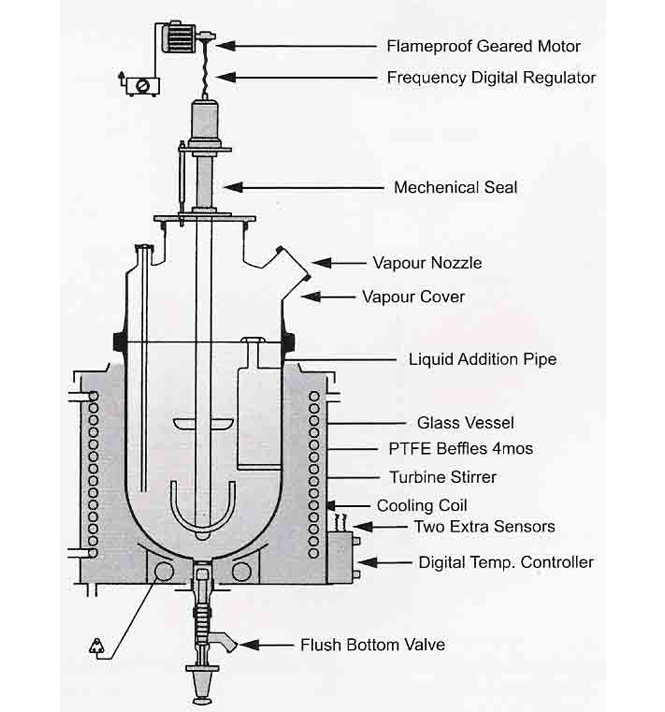

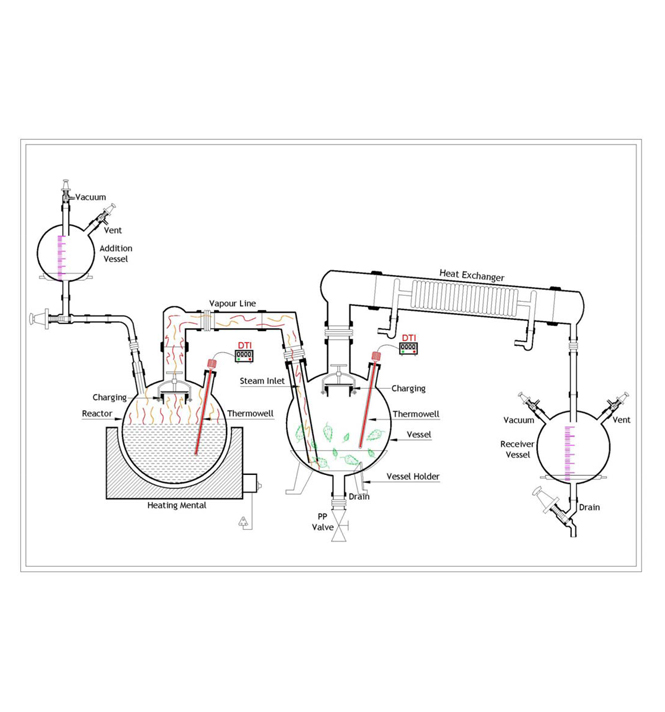

1. Steam Distillation Unit

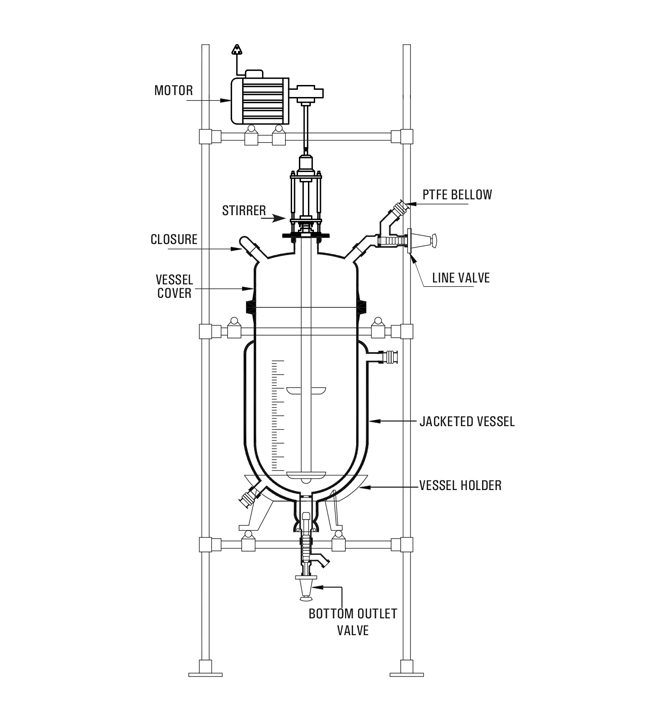

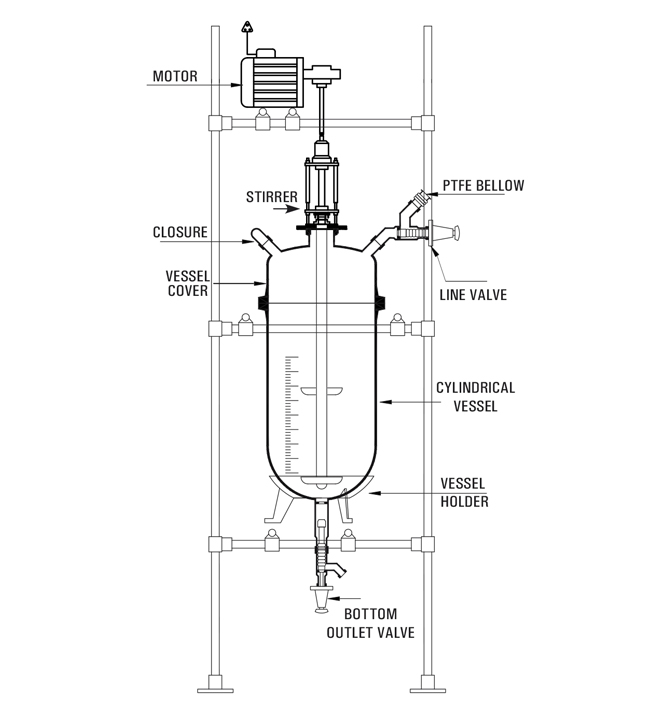

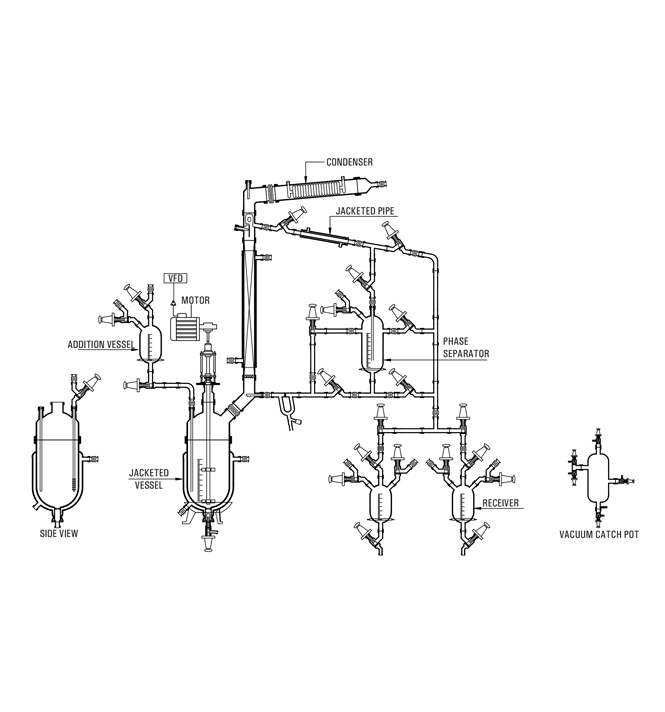

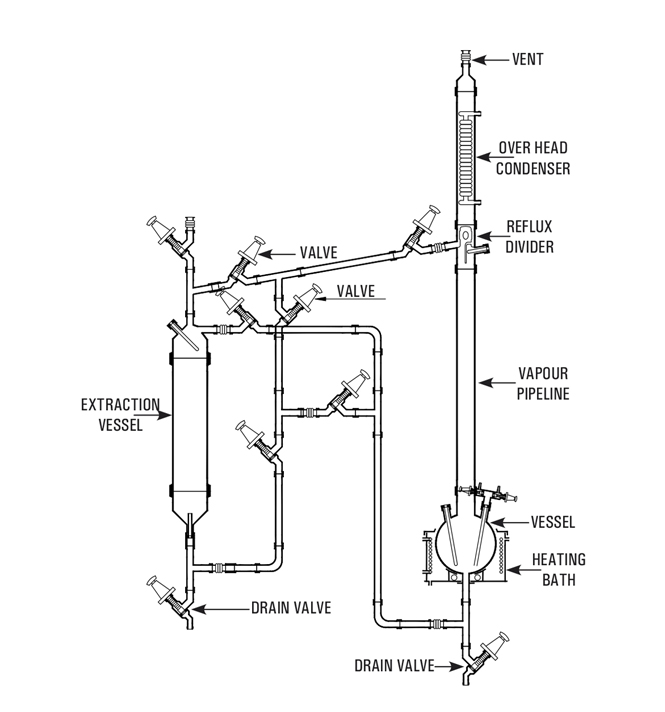

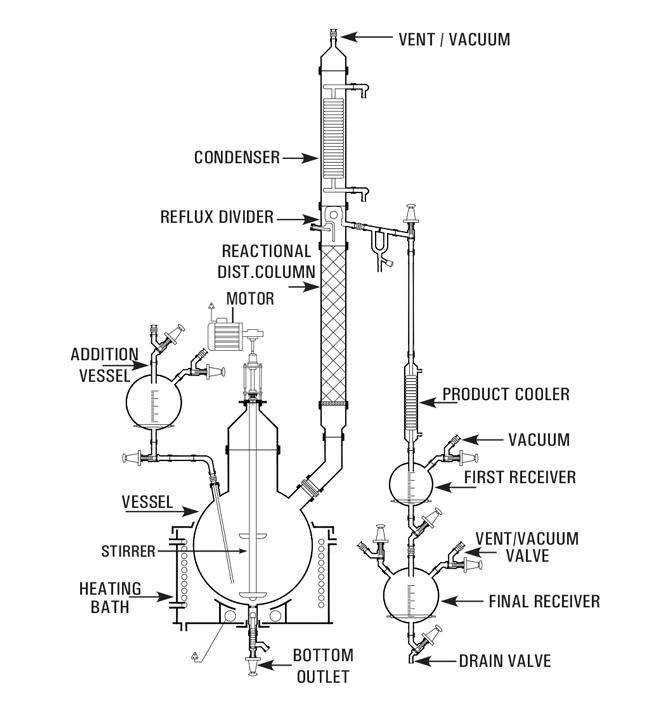

The units come in 10, 20, 50, 100, and 200 L vessels and may operate under air pressure and full vacuum.

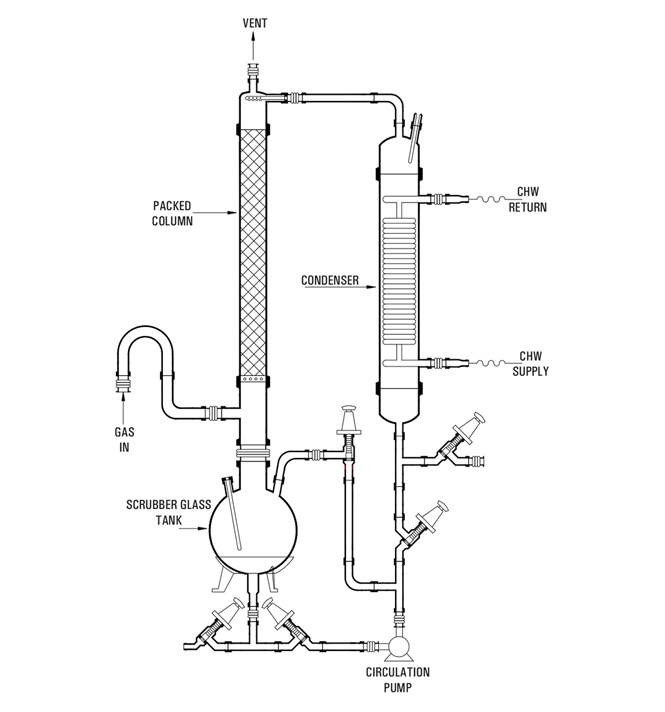

Steam Distillation Unit is a specialized apparatus that extracts essential oils and other volatile chemicals from plant sources. This machine releases aromatic chemicals without destruction by gently heating the botanicals with steam.

As the steam passes through the plant material, it transports the essential oils and other volatile ingredients, which are then condensed and collected. This procedure protects the extracted oils' purity and strength, making them suitable for aromatherapy, perfumery, and natural therapies.

The Steam Distillation Unit assures maximum extraction efficiency and product quality with precise temperature control and effective condensation systems.