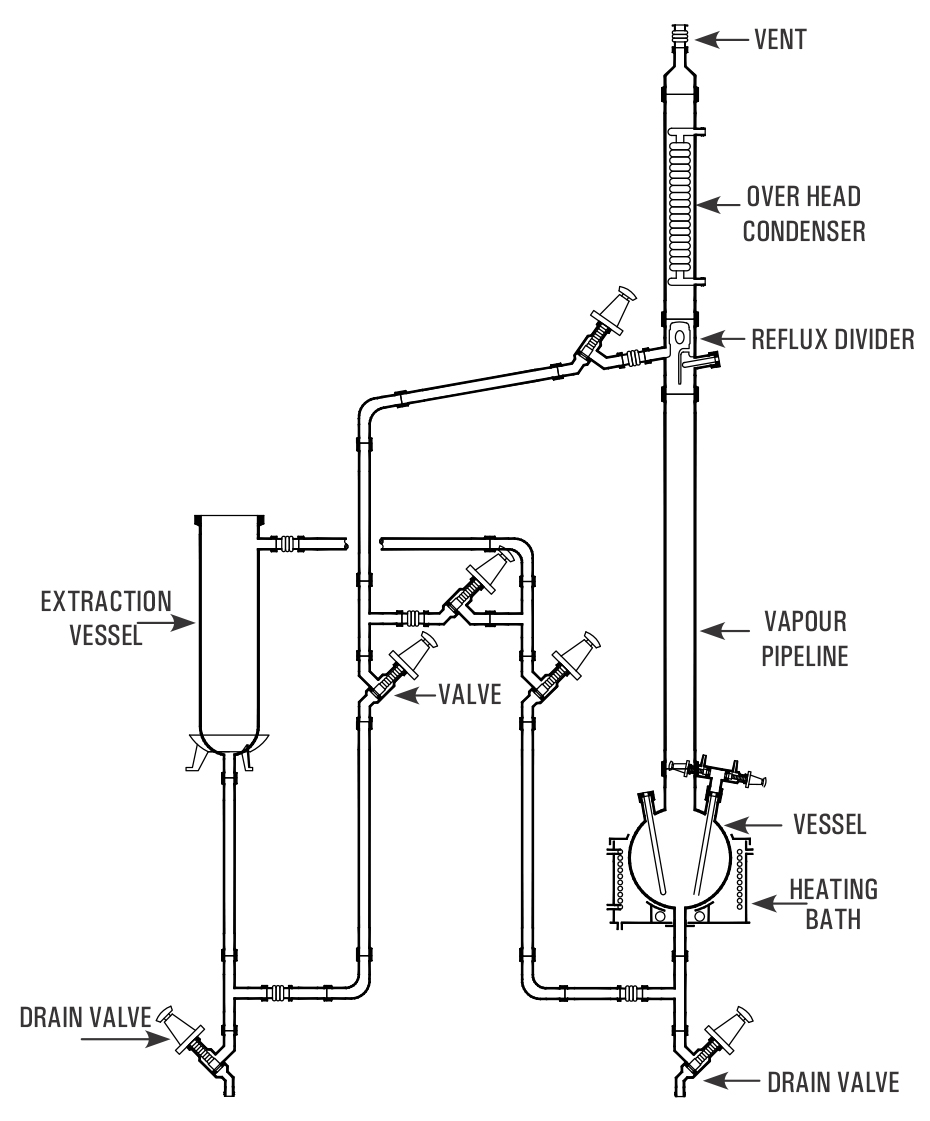

This operation involves preferential solublising of one or more soluble constituents (solutes) of a solid mixture by a liquid solvent. The unit described here is for a semi-batch operation.

The solid to be extracted is put inside a glass fiber bag and placed in an extraction vessel. Solvent from the reboiler is continuously evaporated, condensed and circulated through a reflux divider by means of piping network and valves. When desired/ steady concentration of solute is achieved in the solution the operation is discontinued. The solution is drained off and collected for further use After charging fresh solid in fiber bag and solvent in reboiler, the cycle can be restarted again.

The units are available in vessel sizes of 20, 50, 100, 200 & 300 L and is suitable for operation under atmospheric pressure.

|

Unit Cat. Ref. |

Reactor Capacity |

Bath KW |

Vapour Line |

Extraction Vessel |

Condenser M2 |

|

SLU10 |

10 L |

3.00 |

40mmx1m |

10 L |

0.35 |

|

SLU20 |

20 L |

4.00 |

50mmx1m |

20 L |

0.50 |

|

SLU50 |

50 L |

6.00 |

80mmx1m |

50 L |

1.50 |

|

SLU100 |

100 L |

9.00 |

100mmx1m |

100 L |

1.50 |

|

SLU200 |

200 L |

12.00 |

150mmx1m |

200 L |

2.25 |

|

SLU300 |

300 L |

18.00 |

225mmx1m |

300 L |

4.00 |