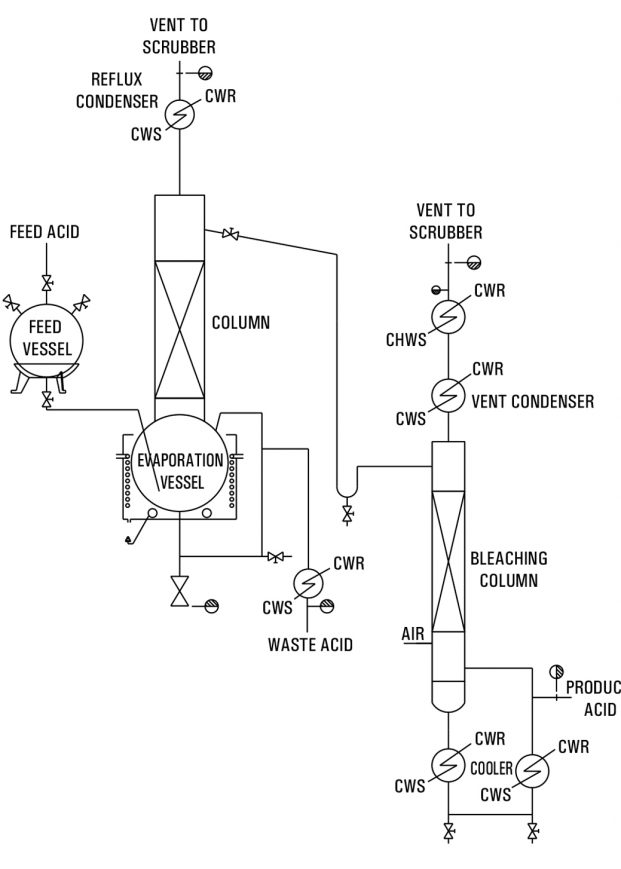

The process of purifying industrial/technical grade nitric acid includes a single-stage distillation that leaves non-volatile contaminants in the still bottoms. A metering pump delivers 69% - 70% concentrated nitric solution from a storage tank into the glass still, which includes an electrically heated oil bath. The acid vapors pass through a packed section that removes mist before entering the glass condenser. Depending on the desired concentration, high purity water can be used to dilute the condensed product before it enters the bleach column. The bleacher's base is where clean air is injected. A condenser vents air and nitrogen oxides into a scrubber. Entrained nitric acid is collected separately from the bleaching column rather than returned to it. Removal of all NOx from electronic-grade nitric acid.

Design Basis & Requirement of Utilities

| Capacity | 40 | kg/hr |

|---|---|---|

| Commercial grade Nitric Acid – 69-70% | 44 | kg/hr |

| Electric Heater | 48 | kw |

| Cooling Water @ 7 deg. C* | 4-5 | Cu.M/hr |

| Space Requirement | 3 x 3 x 8 m |