Advanced Vacuum Evaporation Systems by Goel Impex

Precision Rotary Vacuum Evaporators for Laboratory and Industrial Applications

Goel Impex, a leading manufacturer and supplier of premium laboratory and industrial glassware, offers an innovative range of rotary vacuum evaporators engineered for efficient, safe, and controlled evaporation under reduced pressure. Our rotary film evaporators are widely used in chemical, pharmaceutical, food, and environmental laboratories for vacuum evaporation of water, solvents, and temperature-sensitive substances.

Whether you're looking for an industrial-scale vacuum evaporation system or a laboratory rotary vacuum evaporator, Goel Impex provides advanced rotary vacuum evaporators with high durability, optimal efficiency, and customizable options, making us an established brand in vacuum evaporation equipment across India and globally.

What is a Rotary Vacuum Evaporator?

A rotary vacuum evaporator, commonly known as a rotary evaporator or rotovap, is a vital lab apparatus used for the vacuum evaporation of liquids. This device lowers the boiling point of solvents by applying a vacuum, enabling efficient and gentle removal of solvents from samples at low temperatures.

Also known as a rotary thin film evaporator, it consists of a rotating flask, water or oil bath, vacuum pump, condenser, and vacuum controller for rotary evaporator operations. It’s especially essential in chemical, pharmaceutical, and food industries where precision is paramount.

This method is widely used in chemistry, pharmaceuticals, biotechnology, and food industries for:

Solvent removal and recovery

Sample concentration

Recrystallization

Extraction and purification

Drying of powder or solids

Vacuum evaporation of water and other solvents

Preparation of vacuum evaporated salt

Working of Rotary Evaporator:

A rotary vacuum evaporator operates on the principle of creating a thin film through the rotation of a flask, ensuring maximum surface area for rapid and efficient heat transfer. This rotating action allows uniform heating without the risk of local overheating, which is critical for processing heat sensitive materials.

The application of a vacuum for rotary evaporator use significantly lowers the boiling point of solvents, facilitating vacuum evaporation at reduced temperatures. This minimizes thermal decomposition and shortens residence time, two factors that make the vacuum rotary evaporator ideal for delicate compounds.

Thanks to its versatility, the rotary film evaporator is well-suited not only for solvent recovery and vacuum evaporation of water but also for drying powders, granules, and crystallization processes. Whether in a laboratory vacuum evaporator setup or an industrial vacuum evaporator plant, this equipment delivers high-performance results.

Goel Rotary Film Evaporator (GRFE) is widely recognized across laboratories, research facilities, chemical processing, pharmaceutical, and biotech industries. Its design supports scalability from benchtop vacuum evaporator lab models to industrial wastewater vacuum evaporator systems.

Introduction of Rotary Vacuum Evaporator:

Rotary Evaporator, also known as a rotary vacuum evaporator, is essentially a thin film evaporator.

Salient Features of Goel Rotary Vacuum Evaporator:

1. Universal corrosion-resistant materials are suitable for a wide range of chemical processes.

2. Auto-controlled digital display for rotational speed and heating bath temperature.

3. Real-time digital display of process duration.

4. Automated bath lifting system for ease of use.

5. Auto-lowering of the bath in the event of power failure improves safety.

6. Optional RS-232 interface for data logging and automation.

7. Engineered to operate under high vacuum evaporation conditions.

8. Exceptional performance with heat sensitive and volatile substances.

9. Maintenance-free operation ensures long-term operational reliability.

10. Available in large-volume capacities, up to 400 liters, suitable for a vacuum evaporator for wastewater and industrial use.

Construction of Rotary Vacuum Evaporator:

Goel Rotary Thin Film Evaporators are fully self contained units, primarily comprising the following components:

1. Electrically heated stainless steel (SS) bath with precision controls and adjustable height mechanism.

2. Rotating flask made from durable borosilicate glass, resistant to chemical corrosion and ideal for thin film generation.

3. A motor driven hollow glass shaft, which also functions as a vapor outlet pipe. This shaft is sealed with high-quality Teflon and connected to a vacuum controller for rotary evaporator systems.

4. Condenser and receiver assemblies, crafted based on the evaporator’s size and model specifications, ensure effective vapor condensation and collection.

The equipment is compatible with standard vacuum pumps for rotary evaporator setups, allowing optimal performance across a range of pressures and temperatures.

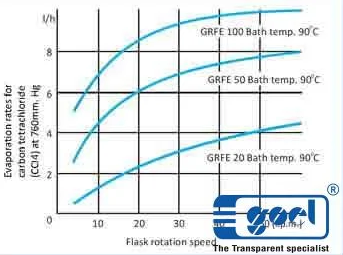

Performance Data of Rotary Vacuum Evaporator:

The efficiency of a rotary vacuum evaporator is influenced by factors such as bath temperature, rotation speed (RPM), flask volume, and vacuum evaporator design. These parameters directly impact the evaporation rate, particularly for solvents like CCl₄.

In general, larger capacity models (e.g., 20L, 50L, 100L) demonstrate increased boil-up rates under identical conditions due to their larger surface area and optimized vacuum evaporation system. The GRFE series supports a wide range of solvent recovery, low temperature vacuum evaporation, and vacuum thermal evaporation technique applications.

Technical Information Related to Various Models of Rotary Vacuum Evaporator are Furnished Below:

Optional for Vaccum Evaporator:

1. Chiller System

2. Vacuum Pump with Configuration

| Model | Rotating Flask Capacity (ltrs.) |

Rotating Speed (rpm) |

Electric Motor Rating |

Condense Cooling Area |

Receiver Flask Capacity (ltrs.) |

Power Supply (Volt/Hz) |

Bath Rating |

|---|---|---|---|---|---|---|---|

| GRFE2 | 2 | 0-80 | 40 Watt | 0.15 | 1 | 230 V, 50 Hz | 2 |

| GRFE3 | 3 | 0-80 | 40 Watt | 0.15 | 1 | 230 V, 50 Hz | 2 |

| GRFE5 | 5 | 0-80 | 40 Watt | 0.15 | 2 | 230 V, 50 Hz | 2 |

| GRFE10 | 10 | 0-80 | 0.25 HP | 0.20 | 5 | 230 V, 50 Hz | 4 |

| GRFE20 | 20 | 0-80 | 0.25 HP | 0.30 | 10 | 230 V, 50 Hz | 4 |

| GRFE50 | 50 | 0-80 | 0.25 HP | 0.50 | 20 | 230 V, 50 Hz | 6 |

Renowned for precision and durability, GOEL is an associated name in rotary vacuum evaporators in India, setting industry benchmarks through innovation, quality, and reliability.

Rotary Vacuum Evaporator Working Principle

The rotary vacuum evaporator working principle is based on reducing atmospheric pressure using a vacuum, which lowers the boiling point of the solvent. The solution is placed in a rotating flask that increases surface area, and the heat from a bath facilitates evaporation. The vapor is then condensed and collected separately.

This vacuum thermal evaporation technique ensures gentle processing of heat-sensitive substances, making it ideal for the vacuum evaporation of water, alcohols, and other solvents in research and production.

Key Components:

1. A sample solution is placed in a rotating evaporation flask.

2. The system is evacuated using a vacuum pump for rotary evaporator, reducing the pressure inside.

3. Gentle heating is applied via a heated water or oil heating bath.

4. The solvent evaporates at a reduced temperature.

5. Vapors are condensed and collected in a separate receiver flask.

This setup ensures efficient separation while preserving sample integrity, ideal for delicate extractions.

Key Features and Specifications of Vacuum Evaporator

At Goel Impex, our rotary vacuum evaporators are built with precision components and innovative design to maximize safety and performance.

Rotary Vacuum Evaporator Specifications:

Capacity: 0.5L to 100L (lab to industrial scale)

Vacuum Level: Up to 1 mbar using a compatible vacuum pump for rotary evaporator

Temperature Range: Ambient to 180°C

Construction/Material: High-grade borosilicate glass and PTFE

Drive System: Brushless DC motor for silent operation

Rotation Speed: Adjustable from 20 to 280 RPM

Heating Bath: Digital temperature control, ambient to 180°C

Vacuum Control: Digital or analog vacuum controller for rotary evaporator

Condensers: Vertical or diagonal options available

Vacuum Pump Compatibility: Suitable with all major vacuum pumps for rotary evaporator models

We also provide vacuum insulated evaporator diagrams and system layouts upon request to support integration into your lab or production facility.

Rotary Vacuum Evaporator SOP (Standard Operating Procedure)

Understanding the SOP for rotary vacuum evaporator is essential for ensuring safe and effective operation.

SOP for Rotary Vacuum Evaporator:

1. Assemble all glassware and secure with clamps.

2. Fill the water/oil bath to the required level and set temperature.

3. Load the sample into the flask.

4. Start rotation and apply vacuum using a rotary vacuum pump.

5. Adjust rotation speed and monitor evaporation.

6. Collect condensed solvent in the receiving flask.

7. Turn off vacuum and rotation after evaporation is complete.

8. Carefully remove and clean all components.

Our detailed rotary vacuum evaporator SOP is available with every unit to guide safe lab practices.

Applications of Rotary Vacuum Evaporator

Goel Impex’s rotary film evaporators are used in diverse industries, including:

Chemical Industries: Solvent recovery, intermediate concentration.

Pharmaceuticals: Rotary thin film evaporator for bio-extracts.

Biotechnology: For sample preparation and concentration of biological samples.

Food and Beverages: Aroma extraction, vacuum evaporator for wastewater.

Environmental Labs: Heavy metal analysis, vacuum evaporation method testing.

Academic & Research Institutions: Organic synthesis, laboratory vacuum evaporator.

Environmental Research: Vacuum evaporator for wastewater treatment.

Salt Production: Supporting vacuum evaporated salt extraction.

Types of Vacuum Evaporator Systems We Offer

Goel Impex offers a wide selection of vacuum evaporation equipment/machines suited for both lab and industrial use, including:

Laboratory Vacuum Evaporator

Industrial Vacuum Evaporators

Standard Rotary Vacuum Evaporator

Rotary Thin Film Evaporator

Rotary Film Evaporator

Vacuum Evaporator for Wastewater

Heat Pump Vacuum Evaporators

Low Temperature Vacuum Evaporator

Vacuum Distillation Evaporator

Vacuum Pan Evaporator

Vacuum Evaporator Plant

Single-stage vacuum evaporators

Multiple Effect Evaporator Under Vacuum

Vacuum Evaporation Equipment & Machines

All systems come with advanced vacuum evaporation deposition and vacuum evaporation technique designs to meet rigorous industry standards.

Vacuum Evaporation Techniques, Equipment & Related Systems

We offer turnkey vacuum evaporation systems with fully integrated controls, precision-engineered vacuum evaporation equipment/machines, and energy-efficient rotary vacuum pumps and evaporators techniques. Our portfolio includes:

Rotary Vacuum Evaporator

Vacuum Evaporator Design

Vacuum Evaporation Process ensures safe recovery of solvents

Vacuum Evaporation System increase energy efficiency

Vacuum Evaporator Plant setups for large-scale industries

Vacuum Evaporation Equipment includes condensers, flasks, controllers, and pumps

Vacuum evaporation Machine for continuous operation

Vacuum Evaporation Principle of boil solvent at low pressure and temperature

Vacuum Evaporation Method for continuous or batch operations

Vacuum Pan Evaporator for crystallization processes

Vacuum Distillation Evaporator for complex chemical processing

Vacuum Evaporation Deposition for thin film coating

Vacuum Evaporator for wastewater treatment

Rotary Vacuum Evaporator manufacturers

Rotary Vacuum Evaporator suppliers

Laboratory Vacuum Evaporators (Vacuum evaporator lab) units with compact footprint

Heat Pump Vacuum Evaporators for sustainable solutions

Multiple Effect Evaporator Under Vacuum for energy efficiency

Industrial Vacuum Evaporators for scale-up

All systems are integrated with advanced vacuum controllers, safety features, and are compliant with international quality standards.

Vacuum Evaporator Process and Benefits

The vacuum evaporator process offers:

Faster evaporation

Energy savings

Preservation of sensitive materials

Solvent recovery and reuse

Reduced contamination risk

The vacuum evaporation principle ensures safer, greener, and cost-effective separation.

Rotary Film & Thin Film Evaporator Technology

Goel Impex also offers rotary film evaporators and rotary thin film evaporators, designed for continuous processing at low temperatures and under high vacuum. These are especially useful in:

Essential oil production

Natural product extraction

High-purity solvent recovery

Rotary Vacuum Pumps and Evaporators

We provide complete packages including:

Vacuum pumps for rotary evaporator systems

High vacuum options for precision

Vacuum insulated evaporator diagrams for setup planning

Fully integrated vacuum evaporation process control

This ensures hassle-free operation with maximum yield and minimal waste.

Rotary Vacuum Evaporator Uses

Our rotary vacuum evaporator systems have a wide range of applications across industries:

Vacuum evaporation of water in desalination

Vacuum evaporator for wastewater in industrial effluent treatment

Vacuum evaporator lab is used for small-scale synthesis

Vacuum evaporation deposition in material science

Vacuum thermal evaporation technique for semiconductor processing

Vacuum evaporation of salt to produce high-purity products

Vacuum distillation evaporator for separating low-boiling-point compounds

Rotary thin film evaporator applications in pharmaceuticals

Rotary Vacuum Evaporator Price & Options

Looking for the rotary vacuum evaporator price or vacuum evaporator price in India and across the globe? Goel Impex offers affordable pricing based on:

Flask capacity and material

System size

Glassware configuration

Heating mechanism/type (oil/water)

Automation level

Control system

Vacuum system integration

Condenser type

Additional accessories like vacuum insulated evaporator, controllers, and chillers

We provide both economical lab units and custom-built industrial vacuum evaporation machines. For updated vacuum rotary evaporator prices and quotes, please contact us directly to receive our vacuum evaporation equipment catalog.

Why Choose Goel Rotary Vacuum Evaporators?

As a leading rotary vacuum evaporator manufacturer and vacuum evaporator supplier in India, Goel Impex delivers:

Over two decades of industry expertise in rotary vacuum evaporator manufacturing

Custom-designed solutions for research and industrial sectors

High-quality, ISO-certified products

Competitive vacuum evaporator price

Durable and chemically resistant materials

Turnkey solutions for vacuum evaporation & distillation

High-precision vacuum and temperature control

Expert support for rotary vacuum evaporator SOP, maintenance, and troubleshooting

Nationwide and global shipping

Full service from design to installation

Reliable after-sales suppor

Global supplier of vacuum evaporation deposition tools

Goel Impex is a leading vacuum evaporators manufacturer, delivering quality and reliability across lab and industrial settings. Our focus on performance, affordability, and compliance makes us your ideal partner in rotary vacuum evaporator suppliers.

Contact Goel Impex for Your Rotary Vacuum Evaporator Needs

Ready to improve your lab or industrial process with the most reliable rotary vacuum evaporator systems? At Goel Impex, we’re committed to delivering excellence in vacuum evaporation equipment with end-to-end support and global delivery.

Get in touch with us for expert consultation on the right vacuum evaporation system for your requirements. Whether you're searching for a laboratory vacuum evaporator, an industrial vacuum evaporator, or want to learn more about rotary vacuum evaporator uses, our team is here to help.