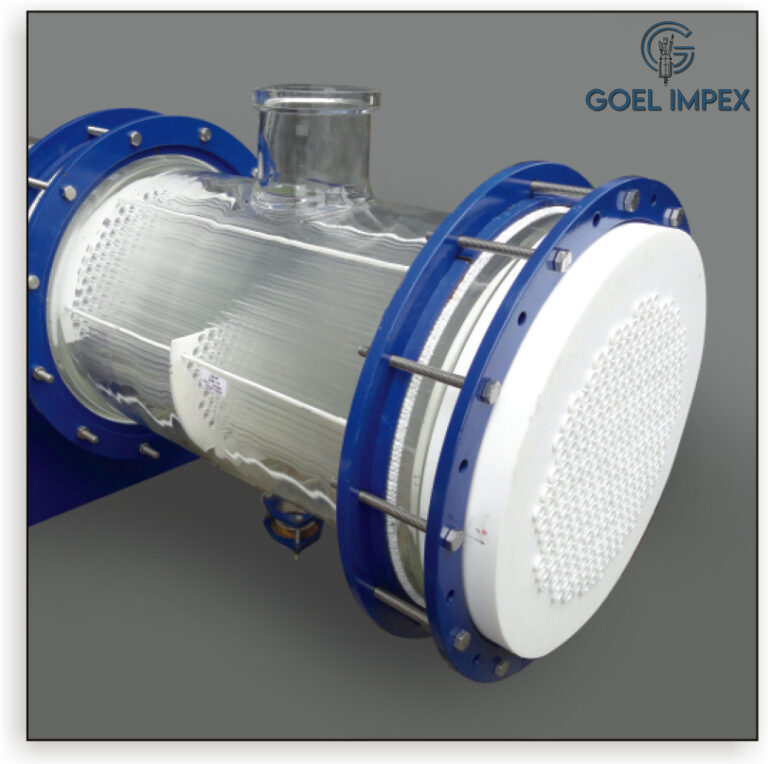

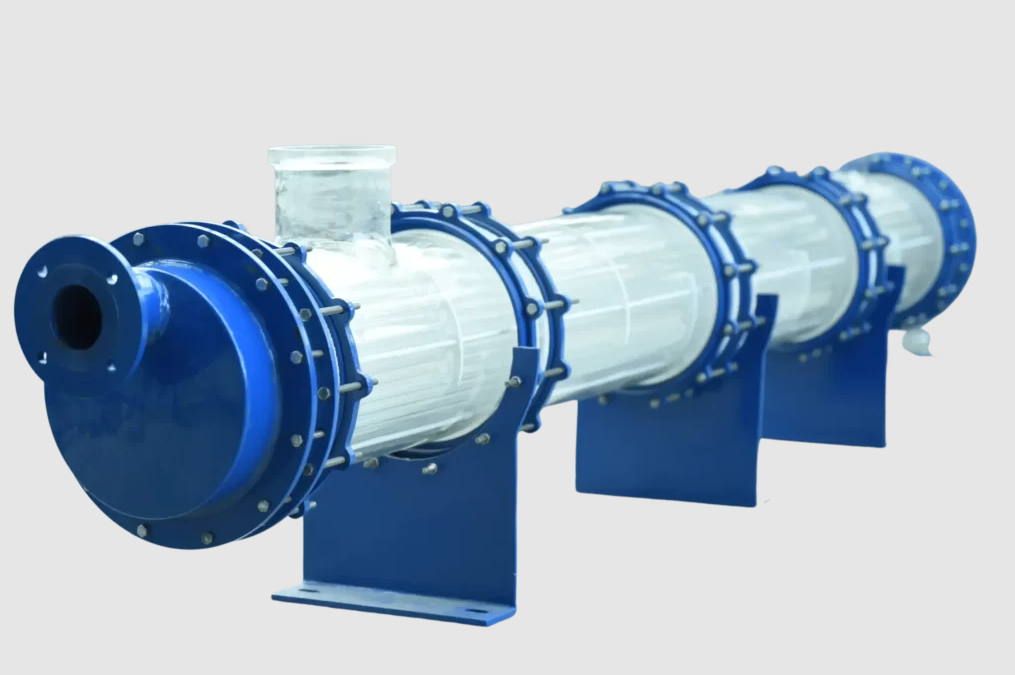

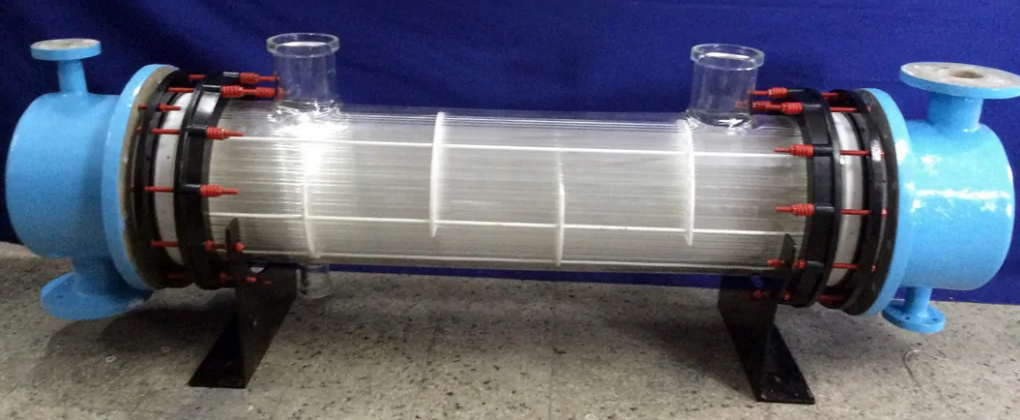

Shell and Tube Heat Exchanger by Goel Impex provide an optimal combination of large surface area, efficient heat transfer, and compact design, making them ideal for industrial applications. These heat exchangers are widely used for cooling, heating, condensation, and evaporation across various industries. As a leading manufacturer of glass shell and tube heat exchangers in India, Goel Impex is recognized for its high-quality products and strong market presence.

What is a Shell and Tube Heat Exchanger?

A shell and tube heat exchanger is a widely used heat transfer device that efficiently exchanges heat between two fluids. It consists of a cylindrical shell containing multiple tubes, allowing one fluid to flow inside the tubes while the other flows around them within the shell. This design ensures effective heat transfer and is commonly used in chemical processing, pharmaceuticals, and petrochemicals.

Key Features of Shell and Tube Heat Exchangers :

- Superior Corrosion Resistance – A cost-effective alternative to expensive materials like graphite, Hastelloy, copper, titanium, tantalum, and other exotic metals.

- Efficient Heat Transfer Efficiency – Smooth glass surfaces prevent fouling, ensuring optimal thermal performance.

- Flexible Installation Options – Can be installed in both vertical and horizontal orientations.

- Easy Maintenance & Cleaning – Quick tube replacement for hassle-free repairs and upkeep.

- Wide Range of Heat Transfer Areas (HTA) – Available in multiple sizes to meet diverse industrial needs.

- Lightweight & Easy to Install – Simplifies handling and reduces installation costs.

- Cost-Effective Solution – Delivers high efficiency at an economical price point.

- Ideal for Compact Spaces – Ideal for applications requiring large HTAs in compact setups.

Advantages of Shell and Tube Heat Exchanger Over Conventional Coil Type Heat Exchangers :

- The shell and tube heat exchanger offers an overall heat transfer coefficient nearly three 3 higher than a coil-type heat exchanger, ensuring efficient thermal exchange.

- With a minimal pressure drop, the shell and tube heat exchanger outperforms coil-type heat exchangers, where the coil side experiences a pressure drop of 2-3 kg/cm².

- For large-scale heat transfer applications, the shell and tube heat exchanger is the best solution, providing a high heat transfer area to meet industrial demands.

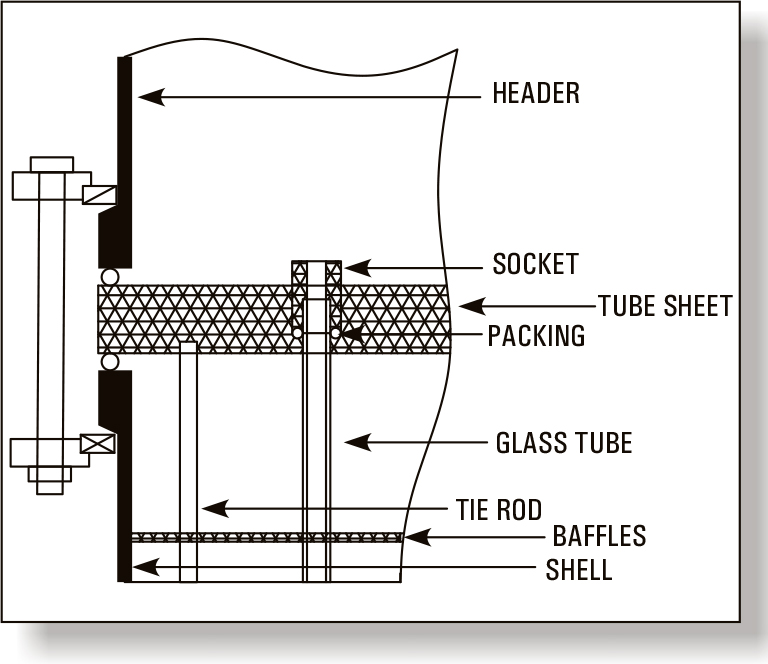

Construction Features of Shell and Tube Heat Exchanger :

The Shell and Tube Heat Exchanger from Goel Impex is designed for efficient heat transfer, featuring high-quality glass tubes individually sealed into a PTFE tube sheet using specialized PTFE sockets and packing. This advanced ferrule-type sealing allows for easy tube replacement and hassle-free cleaning, ensuring long-term performance.

Additionally, strategically placed baffles on the shell side improved heat transfer efficiency by increasing turbulence. For a detailed view of the construction, refer to the provided diagram.

- The Made from SCHOTT DURAN.

- Joint less tubes offer better pressure rating.

TYPE:

Three basic versions * are available :

|

Material Of Construction of Shell and Tube Heat Exchanger |

||||

| Model | Shell | Tube | Header | Duty |

| RGG | Glass | Glass | Glass | For heat transfer between two aggressive media. |

| RGM | Glass | Glass | Steel/FRP | For heat transfer between aggressive media in shell & non-aggressive media in tubes. |

| RMG | Steel/FRP | Glass | Glass | For heat transfer between aggressive media in tubes & non-aggressive media in shell |

|

* GOEL provides assistance to clients for selecting the right model for specific duty. |

||||

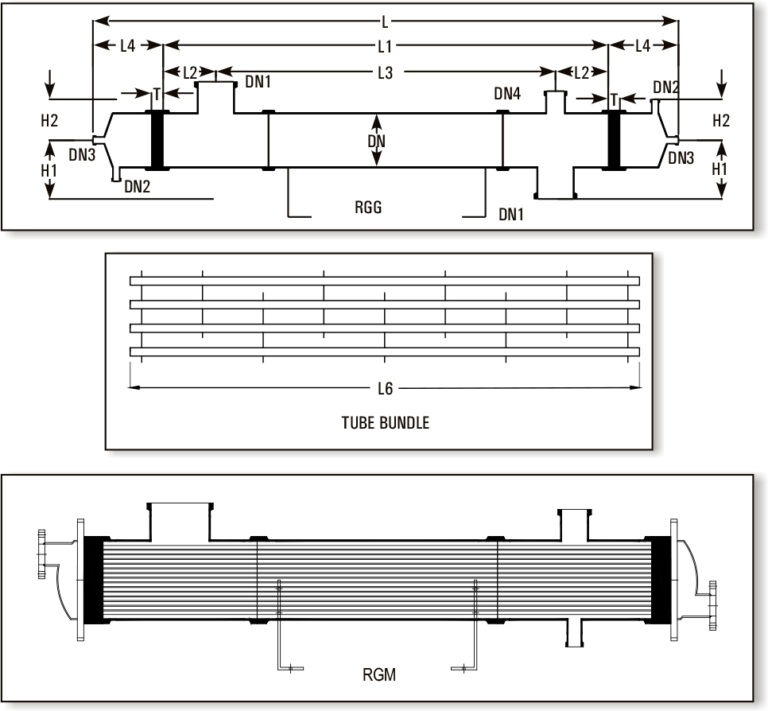

Dimensional Specifications of Shell and Tube Heat Exchanger :

When selecting a shell and tube heat exchanger, understanding its dimensional specifications is crucial for optimal performance. The size and configuration depend on factors like heat transfer area, flow rates, and application requirements. Goel Impex uses HTRI software to design optimal/economical solutions.

At Goel Impex, we offer customizable shell and tube heat exchangers designed to meet industrial needs. Our heat exchangers come in various shell diameters, tube lengths, and material options to ensure efficient heat exchange and durability.

Key dimensions include shell diameter, tube bundle diameter, tube length, tube pitch, and baffle spacing. These specifications determine the heat transfer efficiency, pressure drop, and overall system compatibility. Our designs adhere to international standards, ensuring reliability in chemical, pharmaceutical, and industrial applications.

|

Cat.Ref. |

6/3 |

6/4 |

6/5 |

6/6 |

9/6 |

9/8 |

9/10 |

9/12 |

12/12 |

12/16 |

12/21 |

12/25 |

|

Area (m2) |

3 |

4 |

5 |

6 |

6 |

8 |

10 |

12 |

12 |

16 |

21 |

25 |

| DN |

150 |

225 |

300 |

|||||||||

| DN1 |

80 |

100 |

150 |

|||||||||

| DN2 |

50 |

80 |

80 |

|||||||||

| DN3 |

25 |

40 |

40 |

|||||||||

| DN4 |

50 |

50 |

50 |

|||||||||

| H1 |

175 |

250 |

300 |

|||||||||

| H2 |

150 |

200 |

250 |

|||||||||

| L |

2500 |

3100 |

3700 |

4300 |

2620 |

3220 |

3820 |

4520 |

2550 |

3150 |

3950 |

4550 |

| L1 |

1900 |

2500 |

3100 |

3700 |

1900 |

2500 |

3100 |

3800 |

1800 |

2400 |

3200 |

3800 |

| L2 |

150 |

150 |

150 |

150 |

225 |

225 |

225 |

225 |

225 |

225 |

225 |

225 |

| L3 |

1600 |

2200 |

2800 |

3400 |

1450 |

2050 |

2650 |

3350 |

1350 |

1950 |

2750 |

3350 |

| L4 |

250 |

250 |

250 |

250 |

300 |

300 |

300 |

300 |

300 |

300 |

300 |

300 |

| L5 |

125 |

125 |

125 |

125 |

175 |

175 |

175 |

175 |

175 |

175 |

175 |

175 |

| L6 |

1980 |

2580 |

3180 |

3780 |

2000 |

2600 |

3200 |

3900 |

1930 |

2530 |

3330 |

3930 |

| T |

50 |

60 |

75 |

|||||||||

| No. of Tubes |

37 |

73 |

151 |

|||||||||

| No. of Baffles |

11 |

15 |

19 |

23 |

7 |

9 |

13 |

17 |

5 |

7 |

9 |

11 |

Shell and Tube Heat Exchanger Range of Applications :

- Wide Temperature Compatibility – The Shell and Tube Heat Exchanger operates efficiently within a permissible temperature range of -40°C to 150°C on both shell and tube sides.

- High Thermal Resistance – Designed to handle a maximum permissible temperature difference of 120°C between the shell and tube sides.

- Vacuum & Pressure Handling – All sizes and models are engineered to withstand full vacuum on both sides, ensuring reliable performance.

The maximum permissible pressures for various configurations are detailed in the table below:

|

Maximum Permissible Pressure Range, Kg/cm2(g) |

||||

| Model |

Side |

150DN |

225DN |

300DN |

| RGG |

Shell |

2.0 |

1.0 |

1.0 |

| RGM |

Shell |

2.0 |

1.0 |

1.0 |

| RMG |

Shell |

3.5 |

3.5 |

3.5 |

Goel Impex provides recommended operating data for each specific case, considering the relationship between pressure, temperature, size, and model. The listed application ranges represent admissible limiting values. For precise operational guidance, consult Goel Impex's expert recommendations.

Shell and Tube Heat Exchanger Performance & Design Data :

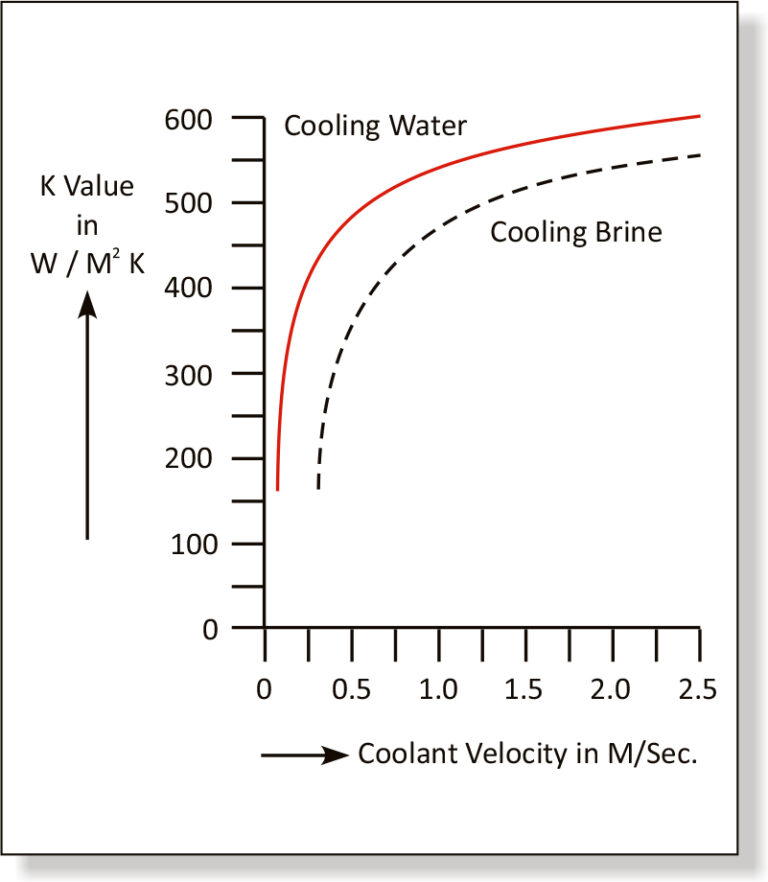

Shell & tube heat exchangers are widely recognized for their high heat transfer efficiency and robust performance. Their design allows for optimal heat exchange, where the relationship between heat transfer and fluid velocity is clearly illustrated in the accompanying diagram.

At Goel Impex, we select the most suitable shell and tube heat exchanger based on your specific operational data. Our precise engineering and strict quality assurance guarantee maximum efficiency, reliability, and cost-effectiveness.

For preliminary sizing, refer to the typical heat transfer coefficients provided below:

|

U-Values |

||||

| Media |

Use |

kcal/m2hrk |

W/m2k300 |

|

| DN | ||||

| Steam water |

condensation |

350-550 |

410-640 |

|

| Water – water |

cooling |

250-350 |

290-410 |

|

| Water – air |

cooling |

30-60 |

35-70 |

|

Shell and Tube Heat Exchanger Design

The design of a shell and tube heat exchanger depends on process requirements, such as pressure, temperature, and heat transfer efficiency. Key design elements include:

Shell: The outer cylindrical body that holds the tubes and provides the secondary fluid path.

Tube: A bundle of tubes where the primary fluid flows, enabling efficient heat exchange.

Tube Sheets: Plates that hold the tubes in place and separate the fluids.

Baffles: Internal plates that direct fluid flow and improve heat transfer efficiency.

Inlet & Outlet Nozzles: Openings through which fluids enter and exit the heat exchanger.

Head (End Cover):Sealed section at each end of the exchanger, allowing fluid to flow through the tubes.

The design depends on factors such as fluid properties, pressure, temperature, and required heat exchange rate. Goel Impex offers custom-designed shell and tube heat exchangers to meet industry-specific requirements.

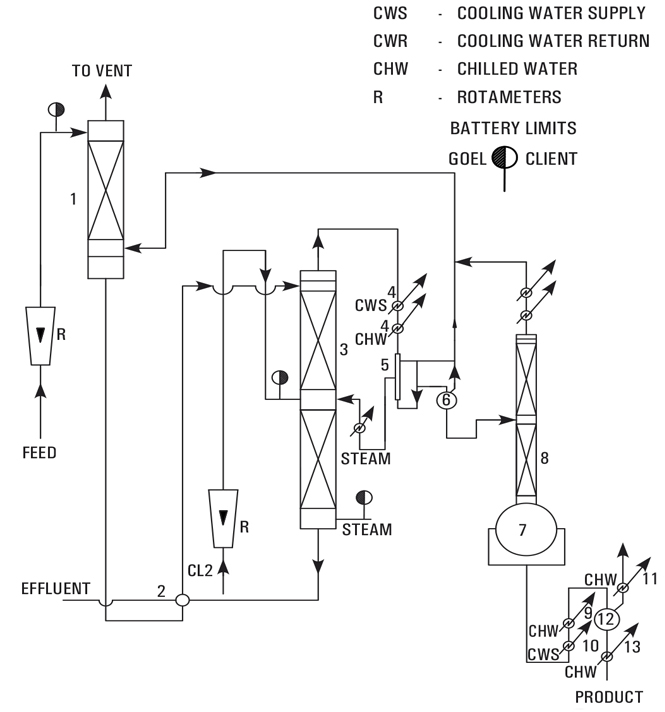

Shell and Tube Heat Exchanger Diagram

A shell and tube heat exchanger diagram visually represents its structure and working principle. The diagram typically includes:

Shell side and tube side fluid flow directions

Baffles for enhanced turbulence and heat transfer

Flow paths showing heat exchange mechanisms

Tube bundle arrangement (U-tube or straight-tube design)

Inlet and outlet connections for both fluids

This diagram helps engineers understand the working process and aids in system optimization.

Goel Impex is a trusted manufacturer of high-quality shell and tube heat exchangers designed for durability and efficiency. Our heat exchangers are built with premium borosilicate glass and corrosion-resistant materials, ensuring long-lasting performance.

Looking for a reliable shell and tube heat exchanger manufacturer? Get in touch with Goel Impex today! Our experts will help you select the right heat exchanger design to optimize your industrial processes.