Commercial Hydrochloric Acid is available as a 30% aqueous solution. However, for certain applications, e.g., bulk drugs and pharmaceuticals, HCL must be in an anhydrous state for critical reactions where moisture cannot be tolerated. Such users generate anhydrous HCL from commercial grade for their captive consumption.

HCL Gas Generation Unit, also known as Dry HCL Gas Generator System, is an essential component in many industrial processes that require hydrochloric acid. These devices efficiently generate high-purity HCL gas by reacting sodium chloride with sulfuric acid. The produced gas has numerous applications, including chemical synthesis, pharmaceutical manufacture, and wastewater treatment. These units use innovative technology and precise control systems to ensure reliable and constant gas output while reducing environmental effects.

Dry HCL gas generation plants, designed for safety and convenience of operation, provide a low-cost alternative for sectors that require a consistent supply of high-quality hydrochloric acid gas. Trust in their ability to handle your industrial needs efficiently and sustainably.

Goel Impex provides high-quality HCL Gas Generators. Our latest Anhydrous Dry HCL Gas Generation Systems are designed to meet the highest standards of efficiency and reliability. Whether you need a Dry HCL Gas Generator, a Dry HCL Gas Generator Plant, or an HCL Gas Generation Unit, we have the expertise and technology to fulfill your requirements.

Capacity

20Kg/Hr to 200Kg/Hr

Unique Features

- Customizable to various production capacities.

- User-friendly interface with advanced control systems.

- A compact and robust design ensures longevity.

- Leakproof System.

- User-friendly and Environmentally friendly.

- Integrated safety measures provide high conversion and recovery rates, making it.

HCL Gas Generator Ideal For

- API and Bulk Drug Pharmaceutical Companies.

- Agrochemical Manufacturers

- R&D

Why Choose Goel Impex's Anhydrous HCL Gas Generation Unit?

Opt for unrivalled quality and innovative solutions with our Anhydrous HCL Gas Generation Unit. Whether you aim for purity, controlled generation, scalability, or sustainability, we promise to meet and exceed your expectations, propelling your operations to new heights of efficiency and productivity!

What is an HCL Gas Generator?

An HCL Gas Generator is a sophisticated device engineered to produce hydrogen chloride (HCL) gas. This gas is crucial in various industrial applications, including chemical synthesis, pharmaceuticals, and semiconductor manufacturing. Our Dry HCL Gas Generator Plants are designed to generate anhydrous HCL gas with exceptional purity, ensuring optimal performance for your specific applications.

Methods of HCL Gas Generator

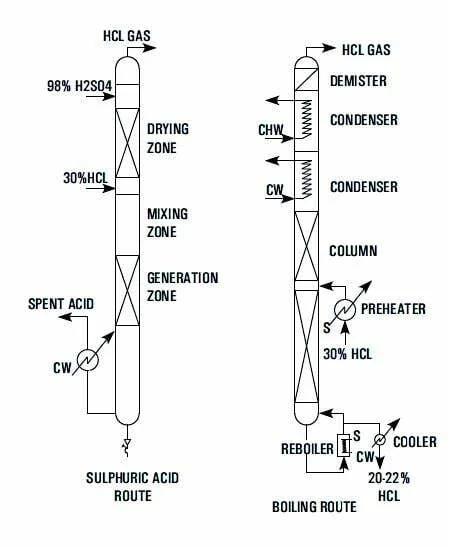

Industries for HCL Gas Generator have adopted several methods. However, generation by the sulphuric acid route and boiling route are commonly practiced. We also offer a calcium chloride route for the HCL gas generator.

Each method has distinct advantages that cater to different industrial requirements.

Sulphuric Acid Route

The Sulphuric Acid Route is a highly efficient method for generating HCL gas. This process involves the reaction of sulphuric acid with sodium chloride (salt) to produce HCL gas. Here’s a step-by-step breakdown:

Reaction: Sulphuric acid (H2SO4) reacts with sodium chloride (NaCl) to form sodium bisulphate (NaHSO4) and HCL gas.

Separation: The HCL gas is then separated from the mixture.

Purification: The gas is purified to remove impurities, ensuring it is anhydrous and ready for industrial use.

Advantages of the Sulphuric Acid Route:

High purity of HCL gas.

Efficient and cost-effective for large-scale production.

Boiling Route

The Boiling Route involves the generation of HCL gas through the boiling of hydrochloric acid. This method is suitable for applications requiring smaller quantities of HCL gas. Here’s how it works:

Boiling: Hydrochloric acid (HCL) is boiled to produce HCL gas.

Collection: The generated gas is collected and condensed.

Drying: The gas is dried to ensure it is anhydrous.

Advantages of the Boiling Route:

Simpler setup and operation.

Ideal for smaller-scale or on-demand HCL gas production.

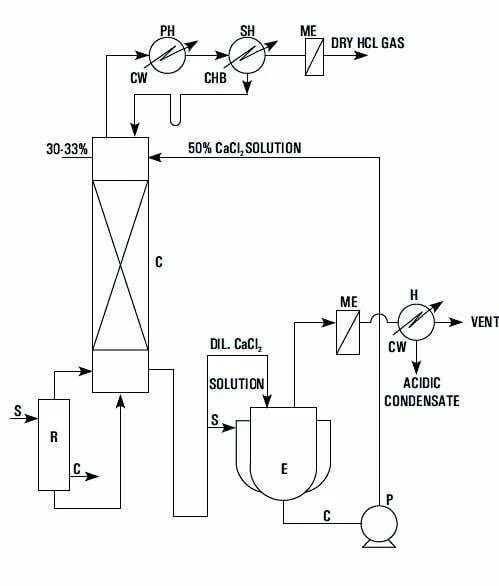

Calcium Chloride Route

Calcium chloride effectively removes water and generates dry, anhydrous HCL gas.

The Calcium Chloride Route is another effective method for generating anhydrous dry HCL gas. This process involves the following steps:

Reaction: Calcium chloride reacts with hydrochloric acid to produce calcium chloride and HCL gas.

Gas Collection: The HCL gas is collected as it is released from the reaction.

Drying and Purification: The gas is then dried and purified to ensure it meets the required specifications.

Calcium Chloride Route Working Principle:

Hydrochloric acid and water form a maximum boiling point azeotrope at 11O°C, corresponding to a concentration of 20.24% (w/w) HCL. Adding concentrated CaCl solution to commercial hydrochloric acid eliminates the azeotrope 2 points, and the entire’ HCL becomes available for liberation by distillation. Anhydrous HCL gas generation through the Calcium Chloride Route is the most environmentally friendly technique.

Calcium Chloride Route Process Description:

The above principle- is achieved in practice by feeding metered quantities of commercial HCL and 50% CaCl -solution to a stripping column with a steam 2 heated re-boiler at the bottom. The effluent from the bottom of the column is a dilute acidic calcium chloride solution, which is concentrated to 50% in an evaporator and reused. The vapor leaving is condensed stage-wise with cooling water and chilled brine as coolant. The relatively dry gas passes through a mist eliminator and then through a rotameter to the point of consumption.

How Does the HCL Gas Generation Process Work?

Our HCL Gas Generators employ a meticulous process to ensure the production of pure, dry HCL gas. Here’s a step-by-step overview of the generation process:

Raw Material Feeding: The process begins with carefully feeding hydrochloric acid (HCL) and a dehydrating agent into the generator.

Reaction Chamber: The mixture is introduced into the chamber, undergoing a chemical reaction. The dehydrating agent absorbs the moisture from the hydrochloric acid, producing anhydrous HCL gas.

Gas Cooling: The generated gas is then passed through a cooling system to condense any remaining moisture, ensuring the dryness of the HCL gas.

Purification: The gas is further purified to remove impurities, achieving the desired purity level.

Storage and Utilization: The pure, dry HCL gas is stored in specialized containers or directly supplied to the production line for various industrial applications.

Key Features of Our HCL Gas Generation Units

High Purity Gas Output: Our systems produce HCL gas with exceptional purity, meeting the stringent requirements of various industrial applications.

Safety and Reliability: Safety is our top priority. Our HCL Gas Generation Units have advanced safety features to protect the equipment and operators.

Efficient Performance: Designed for optimal efficiency, our Dry HCL Gas Generators minimize energy consumption while maximizing output.

User-Friendly Design: Our systems are easy to operate and maintain, ensuring minimal downtime and maximum productivity.

Applications of Dry HCL Gas Generators

Dry HCL Gas Generators are vital in numerous industries due to their versatility and efficiency. Key applications include:

Chemical Industry: Used in producing various chemicals, including chlorides, pharmaceuticals, and agrochemicals.

Pharmaceuticals: Essential in synthesizing active pharmaceutical ingredients (APIs) and other drug manufacturing processes.

Semiconductor Industry: Critical for etching and cleaning processes in semiconductor fabrication.

Laboratories and Research: Utilized in various experimental and research applications requiring high-purity HCL gas.

Water Treatment: In pH control and purification processes.

Why Choose GOEL Impex for HCL Gas Generator

At Goel Impex, we are committed to delivering excellence in every aspect of our HCL Gas Generators. Here’s why you should choose us:

Innovative Technology: Our systems incorporate the latest advancements in gas generation technology, ensuring superior performance and reliability.

Customized Solutions: We understand that every industry has unique requirements. Our team works closely with you to design and deliver customized HCL Gas Generation Units that meet your needs.

Comprehensive Support: From installation and commissioning to maintenance and support, we offer end-to-end services to ensure seamless operation of your Dry HCL Gas Generator Plants.

Proven Track Record: We are a trusted name in the industry with years of experience and a portfolio of satisfied clients.

Ready to improve your industrial processes with a reliable HCL Gas Generator? Contact us today to learn more about our products and services. Our team of experts is here to assist you in finding the perfect solution for your HCL gas generation needs.

Contact Goel Impex today to learn more about our Anhydrous Dry HCL Gas Generation Systems and how we can help you achieve your industrial goals.